These filaments contain a significant percentage of metal powders, but also enough plastic to print at low temperatures with any 3D printer. At the same time, they contain enough metal to look, feel and have a weight close to that of a metal object.

Products made of filament containing iron even rust under certain conditions, which adds credibility, but they cannot rust through and deteriorate from this - and this is their advantage over real metal objects.

The advantages of such materials:

- Unique appearance printouts

- Ideal for costume jewelry, figurines, household items and decor

- High strength

- Very little shrinkage during cooling

- Heated table optional

- Low product flexibility, depends on print design

- Not considered safe in contact with food

- Requires fine tuning of nozzle temperature and filament feed rate

- Post-processing of products is necessary - grinding, polishing

- Rapid wear of the extruder nozzle - filament with metal is very abrasive compared to conventional materials

3D metal printing in industry

If you are looking to purchase a real metal 3D printer for enterprise use, then there are two pieces of news for you - good and bad.

The good news is that their range is quite wide and continues to expand - it will be possible to choose a device that meets any technical requirement. Further in the article you can see this.

The bad news is the prices. The cost of professional metal printing printers starts anywhere from $200,000 and goes up indefinitely. In addition, even if you choose and purchase the most inexpensive of them, the purchase of consumables, scheduled maintenance with the replacement of components, and repairs will be a separate blow. We do not forget about the staff and the costs of post-processing products. And at the stage of preparation for printing, you will need special software and people who can handle it.

If you are ready for all these expenses and difficulties - read on, we will present some very interesting samples.

3D metal printing - application

Some industrial sectors already use metal 3D printers, they have become an integral part of the production process, which the average consumer may not be aware of:

The most common example is medical implants and dental crowns, bridges, prostheses, which are already considered the best option for patients. Reason: They can be 3D printed faster and cheaper and tailored to the individual needs of each patient.

The second, equally common example: jewelry. Majority major manufacturers is gradually moving from 3D printing of molds and stencils to direct metal 3D printing, and titanium printing allows jewelers to create designs that were previously impossible.

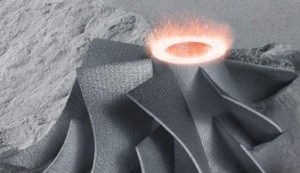

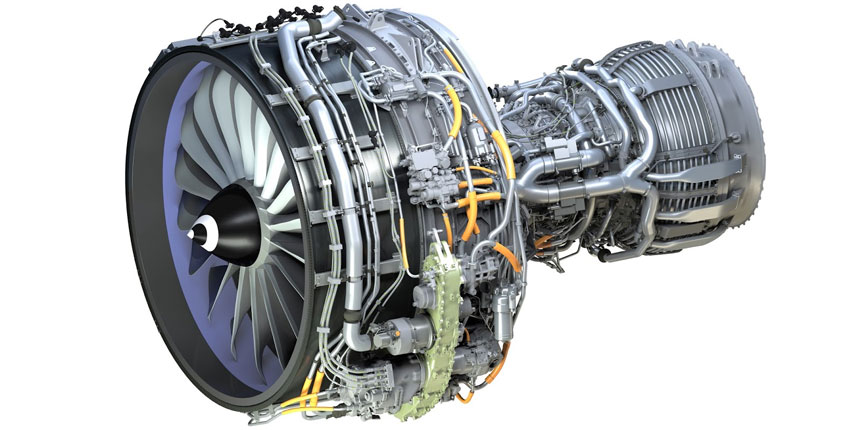

In addition, the aerospace industry is becoming more and more dependent on 3D printed metal products. Ge-AvioAero in Italy is the world's first fully 3D printed factory that produces components for LEAP jet engines.

The next industry using metal 3D printers is the automotive industry. BMW, Audi, FCA are already seriously considering applying the technology to series production, not just prototyping, where they have been using 3D printing for years.

It would seem - why reinvent the wheel? But here, too, 3D metal printing has found application. For several years now, manufacturers of bicycle components and frames have been using 3D printing. Not only in the world, but also in Russia, this has become widespread. Exclusive bike manufacturer Triton is finishing up a project with a 3D printed titanium frame element that reduces weight without compromising strength.

But before metal 3D printing really takes over the world, there are a few major challenges that need to be overcome. First of all, it is the high cost and low speed of production of large series by this method.

3D metal printing - technologies

Much can be said about the use of metal-printing 3D printers. There are specifics, but the main issues are the same as with any other 3D printers: software and hardware limitations, material optimization and multi-material printing. We won't talk about software many, to mention only that the major publishers such as Autodesk, SolidWorks and SolidThinking all develop software products for use in metal 3D printing so that users can bring to life any shape imaginable.

IN Lately examples have emerged that 3D printed metal parts can be as strong as traditionally produced metal components, and in some cases even surpass them. Created using DMLS, the products have the same mechanical properties as those of solid cast counterparts.

Let's look at the available metal 3D printing technologies:

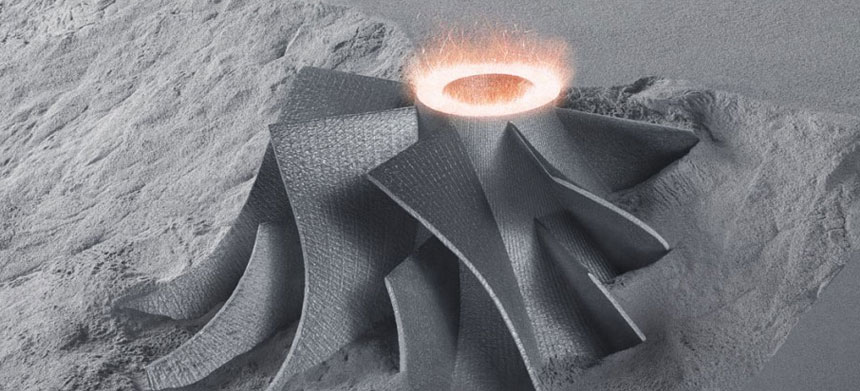

Process #1: Layer by layer powder fusion

The process of 3D printing metals that most major companies use these days is known as powder bed fusion or sintering. This means that a laser or other high-energy beam fuses particles of evenly distributed metal powder into a single whole, creating layers of the product, one after another.

There are eight main manufacturers of metal 3D printers in the world, most of them are located in Germany. Their technologies go under the acronym SLM (Selective Laser Melting) or DMLS (Direct Laser Metal Sintering).

Process #2: Binder Jetting

Another professional method with layer-by-layer bonding is gluing metal particles for subsequent firing in a high-temperature furnace, where the particles are fused under pressure, making up a single metal whole. The printhead applies the coupling solution to the powder substrate in layers, like a conventional printer on sheets of paper, after which the product is sent to firing.

Another similar but different technology based on FDM printing is mixing metal powder into metal paste. Using pneumatic extrusion, the 3D printer extrudes it, much like a 3D construction printer does with cement, to form 3D objects. After the desired shape is printed, the objects are also sintered in an oven. This technology is used by Mini Metal Maker - perhaps the only more or less affordable metal 3D printer ($1600). Add the cost of a small kiln.

Process #3: Welding

You might think that among the metal printing technologies there is no similar to the usual FDM, however, this is not entirely true. You can't melt metal filament in the hot end of your 3D printer, but the big manufacturers have the technology and use it. There are two main ways to print with solid metal material.

One of them is called DED (Directed Energy Deposition), or laser cladding. It uses a laser beam to fuse metal powder that is slowly released and deposited from an extruder, forming layers of an object with an industrial arm.

Usually this is done inside a closed chamber, however, with MX3D as an example, we see the possibility of implementing a similar technology in the construction of a real full-sized bridge, which is due to be printed in 2017 in Amsterdam.

The other is called EBM (Electron Beam Manufacturing), a technology for forming layers of metal raw materials under the influence of a powerful electron beam, with its help create large and very large structures. If you do not work in the defense complex of the Russian Federation or the United States, then you are unlikely to see this technology alive.

A couple more new, barely emerging technologies, used so far only by their creators, are presented below - in the section on printers.

Used metals

Ti - Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing, and by far one of the most versatile as it is both strong and lightweight. It is used both in the medical industry (in personalized prosthetics) and in the aerospace and automotive industries (for the manufacture of parts and prototypes), and in other areas. The only catch is that it is highly reactive, which means it can explode easily when in powder form, and should definitely only be used for printing in an inert Argon gas environment.

SS - Stainless steel

Stainless steel is one of the most affordable metals for 3D printing. At the same time, it is very durable and can be used in a wide range of industrial and artistic applications. This type of steel alloy containing cobalt and nickel has high elasticity and tensile strength. 3D printing of stainless steel is used mainly only in heavy industry.

Inconel - Inconel

Inconel is a modern superalloy. It is manufactured by Special Metals Corporation and is a patented trademark. Consists, for the most part, of nickel and chromium, has high heat resistance. It is used in the oil, chemical and aerospace industries (for example: to create distribution nozzles, on-board "black boxes").

Al - Aluminum

Due to its inherent lightness and versatility, aluminum is a very popular metal for 3D printing applications. It is usually used in the form of various alloys, forming their basis. Aluminum powder is explosive and is used in printing in an inert Argon gas environment.

CoCr - Cobalt Chromium

This metal alloy has a very high specific strength. It is used both in dentistry - for 3D printing of dental crowns, bridges and clasp prostheses, and in other areas.

Cu - Copper

With rare exceptions, copper and its alloys - bronze, brass - are used for casting using burnt patterns, and not for direct metal printing. This is because their properties are far from ideal for industrial 3D printing applications, they are more commonly used in arts and crafts. With great success, they are added to plastic filament - for 3D printing on conventional 3D printers.

Fe - Iron

Iron and magnetic iron ore are also mainly used as an additive to PLA filament. In large-scale industry, pure iron is rarely used, and we wrote about steel above.

Au, Ag - Gold, silver and other precious metals

Most powder fusing 3D printers can work with precious metals such as gold, silver and platinum. The main task when working with them is to ensure the optimal consumption of expensive material. Precious metals are used in 3D printing of jewelry and medical products, as well as in the production of electronics.

Metal 3D printers

#1: Sciaky EBAM 300 - titanium rod

For printing really large metal structures the best choice will be EBAM from Sciaky. This device can be any size, to order. It is used primarily in the US aerospace and defense industries.

How serial model, Sciaky sells the EBAM 300. It has a working area with sides of 5791 x 1219 x 1219mm.

The company claims that the EBAM 300 is one of the fastest commercially available industrial 3D printers. Structural elements of aircraft, the production of which, according to traditional technologies, could take up to six months, are now printed within 48 hours.

Sciaky's unique technology uses a high power electron beam gun to melt 3mm titanium filament, with a standard deposition rate of about 3-9 kg/h.

#2: Fabrisonic UAM - ultrasonic

Another way to 3D print large metal parts is Ultrasound Additive Manufacturing Technology (UAM) from Fabrisonic. The brainchild of Fabrisonic is a three-axis CNC machine with an additional welding head. The metal layers are first cut and then welded together using ultrasound. Fabrisonic's largest 3D printer is the “7200”, which has a build volume of 2 x 2 x 1.5 m.

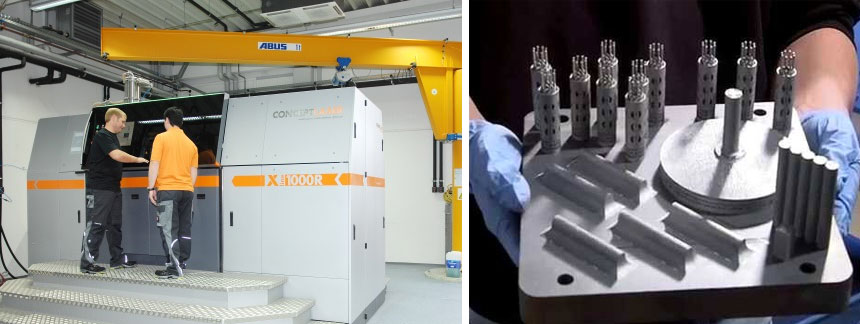

#3: Laser XLine 1000 - metal powder

One of the largest metal powder 3D printers on the market has long been the Concept Laser XLine 1000. It has a build area of 630 x 400 x 500mm and takes up space like a small house.

The German company that made it, which is one of the suppliers of 3D printers for aerospace giants such as Airbus, recently introduced new printer- XLine 2000.

The 2000 has two lasers and an even larger build volume of 800 x 400 x 500mm. This machine, which uses patented LaserCUSING (a type of selective laser melting) technology, can create objects from alloys of steel, aluminum, nickel, titanium, precious metals, and some pure materials (titanium and bar steels.)

All major players in the metal 3D printing market have similar machines: EOS, SLM, Renishaw, Realizer and 3D Systems, as well as Shining 3D, a rapidly growing company from China.

#4: M Line Factory - Modular 3D Factory

Displacement: 398.78 x 398.78 x 424.18mm

1 to 4 lasers, 400 - 1000 watts each.

The M Line Factory concept is based on the principles of automation and interaction.

M Line Factory, from the same Concept Laser and operating on the same technology, does not focus on the size of the workspace, but on the convenience of production - it is a modular architecture apparatus that divides production into separate processes in such a way that these processes can occur simultaneously, not sequentially.

This new architecture consists of 2 independent machine units:

M Line Factory PRD (Production Unit)

The Production Unit consists of 3 types of modules: dosing module, printing module and overflow module (tray for finished products). All of them can be individually activated and do not form one continuous piece of equipment. These modules are transported through a system of tunnels inside the machine. For example, when new powder is supplied, the empty powder storage module can be automatically replaced with a new one without interrupting the printing process. Finished parts can be moved outside the machine and immediately automatically replaced by the next jobs.

M Line Factory PCG (Processing Unit - processing unit)

It is an independent data processing unit that has a built-in sieving and powder preparation station. Unpacking, preparation for the next print job and sieving take place in a closed system, without the participation of the operator.

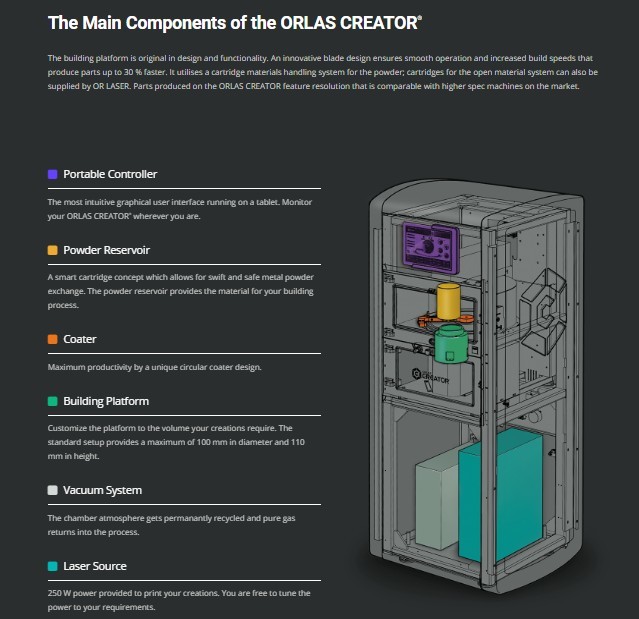

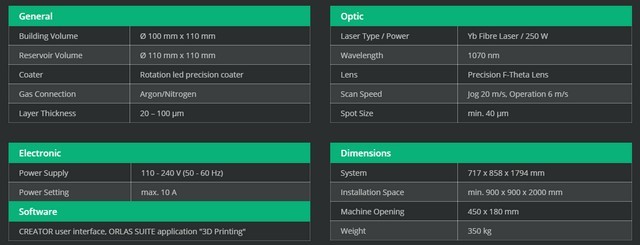

# 5: ORLAS CREATOR - 3D printer ready to go

The creators of ORLAS CREATOR position this 3D printer as the most affordable, easy-to-use and ready-to-use, does not require the installation of any additional components and third-party programs, capable of printing directly from a complete CAD / CAM file of their own design.

All the necessary components are installed in a relatively compact case, which needs a space of 90x90x200 cm. It does not take up much space, although it looks impressive, and it weighs 350 kg.

As can be understood from the table given by the manufacturer, the metal powder is sintered by a rotating laser system, in layers 20-100 µm thick and with a “pixel” size of only 40 µm, in a nitrogen or argon atmosphere. You can connect it to a regular household power supply if your wiring can withstand a load of 10 amperes. Which, however, does not exceed the requirements of an average washing machine.

Laser power - 250 watts. The working area is a cylinder 100 mm in diameter and 110 mm in height.

#6: FormUp 350 - Powder Machine Part Method (PMPM)

The FormUp 350, powered by Powder Machine Part Method (PMPM), was created by AddUp, a joint venture between Fives and Michelin. This is the latest metal 3D printing machine, first introduced in November at Formnext2016.

The principle of operation of this 3D printer is the same as that of the above colleagues, but its main feature is different - it lies in its inclusion in PMPM.

The printer is designed specifically for industrial use, in 24/7 mode, and is designed for just such a pace of work. The PMPM system includes quality control of all components and materials at all stages of their production and distribution, which should guarantee stable high performance quality of work, in which Michelin has a huge long-term experience.

Zack Vader's MagnetoJet technology is based on the study of magnetohydrodynamics, and more specifically, the ability to control molten metal using magnetic fields. The essence of the development is that a drop of a strictly controlled size is formed from molten aluminum, and these drops are used for printing.

The size of such a droplet is from 200 to 500 microns, printing occurs at a speed of 1000 drops per second. Printer working area: 300 mm x 300 mm x 300 mm

Working material: Aluminum and its alloys (4043, 6061, 7075). And, even though it is only aluminum for now, the printer is 2 times faster than powder ones and up to 10 times cheaper.

In 2018, the Mk2 is planned to be released, it will be equipped with 10 print heads, which should give an increase in print speed by 30 times.

#9: METAL X - ADAM - atomic diffusion

Markforged presented new technology Metal 3D printing - ADAM, and a 3D printer working on this technology - Metal X.

ADAM (Atomic Diffusion Additive Manufacturing) is an atomic diffusion technology. Printing is done with metal powder, where the metal particles are coated with a synthetic binder, which is removed after printing, allowing the metal to fuse together.

The main advantage of the technology is the absence of the need to use ultra-high temperatures directly in the printing process, which means that there are no restrictions on the refractoriness of the materials used for printing. Theoretically, the printer can create 3D models from heavy-duty tool steels - now it already prints stainless steel, and titanium, Inconel and D2 and A2 steels are in development.

The technology allows you to create parts with a complex internal structure, such as in a honeycomb or in porous bone tissue, which is difficult with other 3D printing technologies, even for DMLS.

Product size: up to 250mm x 220mm x 200mm. Layer height - 50 microns.

Look, it will soon be possible to print a high-quality knife - from scratch, in a couple of hours, giving it any most intricate design.

Do you want more interesting news from the world of 3D technologies?

We offer printing from the two most common materials for printing on 3D printers from SLM Solutions (Germany) (hereinafter referred to as the “SLM company”)

- 1.2709 - tool steel,

- 1.4404 (316L) - stainless steel.

It is possible to 3D print from other metal powders used for SLM 3D printers, namely 1.2344 (H13), 1.4540 (15-5PH) and 1.4542(17-4PH) by separate agreement.

Metal products that are produced using this 3D printing technology are characterized by a uniform dense structure, high hardness and strength, and corrosion resistance.

SLM 3D printing technology

The essence of SLM (Selective Laser Melting or selective laser melting) 3D printing technology is that the metal powder is completely melted, turning into a homogeneous metal mass.

In the 3D printing process, granular steel powder is spread in a thin layer (from 20 μm - 75 μm to 100 μm) on a platform that descends vertically, and the product is printed using a double laser beam that melts the powder layer by layer. The procedure takes place in a closed chamber with inert gases. At the end of 3D printing, the model cools down, is cleaned of excess powder and transferred to post-processing, the main task of which is to remove support structures.

SLM 3D printer

In the line of SLM 3D printers on this moment There are three 3D printers that differ mainly in the size of the camera. We print on a medium-sized SLM 280 HL system, whose working chamber allows you to create objects with a size of 280 x 280 x 350 mm.

This 3D printer can work not only with steel, but also allows you to print from cobalt-chromium, heat-resistant alloys, aluminum and titanium. The working chamber of SLM's largest 3D printer is designed to produce products with dimensions of 500 x 280 x 325 mm.

If you need to print a product with a rare material or you would like to make a prototype of a large size (up to 500 mm), then we will be happy to discuss our possibilities and perform such work for you.

Features of modeling for 3D printing using the SLM method

The main thing when creating a digital 3D model is to remember that during 3D printing using the SLM method, steel support structures are grown from the base of the 3D printer's camera, which allow you to maintain the shape of the product during the printing process.

As a rule, support structures are automatically built by the 3D printer software, and it is impossible to predict their number in advance. However, the removal of support structures is always painstaking and complex work, which is done almost entirely by hand.

As an experimental work, if necessary, using software, you can specify specific places in the products where support structures should not be grown. However, in this case, there is a risk of changing the geometry of product elements that are left without support.

In addition, sometimes it is practiced to place a 3D model in a 3D printer chamber at a specially calculated angle so that some elements of the product are printed without supports. This achieves the goal of avoiding building support structures at predetermined locations, but at the same time, this approach significantly increases the cost of 3D printing by building long support structures leading to the angled side of the product.

Detailed specifications tool and stainless steel from SLM can be found in the 3D printing materials brochure.

Model design requirements

Minimum wall thickness: 0.4mm

Minimum thickness of raised or engraved part: 0.5mm

Accuracy: 0.2 mm for a detail up to 10 cm and no more than 1-2% for a size over 10 cm

Maximum model size: 280 x 280 x 350 mm

Minimum model size: 3 x 3 x 3mm

Minimum hole diameter for powder removal: 2 mm

Minimum distance between two parts or walls: 1 mm

File Format: STL

Several models in one STL file, connected parts or a part within a part - not allowed.

IN modern life You won’t surprise anyone with a 3D printer that can create three-dimensional models from plastic. However, in cases where it is necessary to create a model with high strength, then such a printer will not help. For these purposes, there is an industrial 3D metal printer, which is characterized by high accuracy and speed of creating metal models.

1. What is a 3D printer

3D printing is the latest technology. We are all familiar with conventional printer on which you can print text or an image. The principle of operation of a 3D printer is similar to a device for two-dimensional printing. The only difference is that the 3D printer prints in three planes. In other words, a three-dimensional printer is able to print almost any three-dimensional object. To obtain the desired part, you will need to simulate it using special software.

1.1. The principle of operation of a 3D printer for metal

The principle of operation of a three-dimensional metal printer is to fuse granules of a special metal powder with a laser.

It should be noted that a 3D printer for metal significantly reduces the time for manufacturing parts, because it takes a lot of time to obtain models that have a complex shape in the traditional way. In addition, the use of special molds for casting or high-precision processing will be required. Obviously, all this requires a fairly large investment of time, as well as finances. This is the main task of a three-dimensional printer - to speed up and simplify the production of metal parts.

In the process of manufacturing the desired part, 3D metal printers use a large number of layers of metal powder. During further processing, this powder is fused into a single piece under the influence of high temperatures.

As you already know, the production of a part begins with the production of its model on a computer. After the part is modeled, the worker proceeds to prepare the printer. To begin with, an electric heater is started, after which a special metal powder is poured into the mold. Next, the form is installed in its place, after which the supply box is filled with metal powder.

Next, the 3D metal printer evens out the top layer of the powder, which is located in the mold. In order to give the future part the required shape, a special binder is used, which is fed to the print heads through tubes. Printheads, executing computer commands, move along a predetermined trajectory, spraying the thinnest layer of a binder strictly in those places where it is necessary.

After the next layer is completed, the metal powder is dried using special heaters that are located above the mold. After that, the shaft applies a thin layer of metal powder, and the print head applies another layer of binder. It should be noted that the layer of metal powder is fractions of a millimeter.

Thus, the required object is formed. After printing is completed, it will be necessary to carry out the laying process - the form with the printed part is placed in a special oven. The temperature in this oven is kept at 180˚С. After some time (up to 24 hours), the liquid evaporates and the binder hardens. Excess powder remaining on the surface is removed by blowing. After that, the parts that are still fragile and porous are subjected to a bronze saturation process. In a special container filled with aluminum oxide. The oxide is needed to support the part during the saturation process. After that, bronze powder is poured into the container, and all this is placed in the oven for a day.

Of course, this process takes a lot of time. However, this method of manufacturing metal parts is much faster than traditional ones.

2. 3D printer prints metal: Video

2.1. Metal powder for 3D printer

As you already know, metal 3D printers use a special metal powder to work. This is a special stainless steel ground powder. In order for the granules not to stick together, the powder is constantly heated. However, other powders can also be used for 3D printing, from tin and aluminum to titanium. To bake and fuse powder granules together, an industrial 3D metal printer is equipped with a special laser that can heat the powder to a sufficiently high temperature.

The type of powder is selected depending on the conditions under which the finished part will be used. So, not all models that were made on a 3D metal printer are 100% metal.

2.2. 3D metal printer and its advantages

Modern 3D printing technology is the optimal solution for many tasks. First, as already mentioned, this technology allows you to significantly save time for the production of parts. In addition, the resulting parts have high accuracy. Among other things, the advantages of 3D printing include the following:

- A 3D printer for metal printing equally easily produces parts of any complexity;

- Low cost of consumables (metal powders);

- It is quite easy to learn how to work with a metal printer, it requires a minimum amount of time;

- Adjustment and diagnostics of the 3D printer is carried out automatically;

- The 3D printer is extremely easy to operate. In addition, no odors or noises are emitted during operation;

- The metal 3D printer is capable of color printing. At the same time, the quality and color depth are absolutely not inferior to conventional printers;

- For the manufacture of parts, only environmentally friendly and safe materials are used.

In addition to the above list, modern metal 3D printers have many more advantages. This explains the very high demand. It should be borne in mind that technologies do not stand still, 3D printing is constantly developing and improving, and in some cases even today it can replace traditional methods of manufacturing metal parts.

There is no hotter trend in 3D printing today than metal. We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials.

Over the past few years, 3D metal printing has been actively gaining popularity. And this is quite natural: each material offers a unique combination of practical and aesthetic qualities, can be suitable for a wide range of products, prototypes, miniatures, decorations, functional details and even kitchen utensils.

The reason metal 3D printing has become so popular is because the printed objects can be mass-produced. In fact, some of the printed parts are just as good (if not better) than those made with traditional methods.

In traditional production, working with plastic and metal can be quite wasteful - there is a lot of waste, a lot of excess material is used. When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings.

So, what do we need to know about metal 3D printing?

3D metal printing at home

If you want to make objects at home that will look like metal, your best bet is to look at metallized PLA filaments (Photo: colorFabb)

Where to start if you want to print metal objects at home? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this.

It is unlikely that in this decade it will be possible to print with liquid metal at home. Until 2020, you probably will not have a printer specialized for this purpose at home. But in a few years, as nanotechnology advances, we may see significant developments in new applications. This can be 3D printed with conductive silver, which will emit in much the same way as it does in 2D home printers. It will even be possible to mix different materials like plastic and metal in one object.

Materials for metal 3D printing at home

Even though you can't print actual metal objects at home, you can turn to plastic filament that has metal powders added to it. Bestfilament, ColorFabb, ProtoPasta, and TreeD Filaments all offer interesting metal-PLA composite filaments. These filaments, containing a significant percentage of metal powders, remain ductile enough to be printed at low temperatures (200 to 300 Celsius) on virtually any 3D printer. At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions.

But you can go further. Typically, up to 50 percent metal powder is added to 3D printing filament. Dutch company Formfutura says they have achieved 85 percent metal powder with 15 percent PLA. These filaments are called MetalFil Ancient Bronze and Metalfil Classic Copper. They can be printed even at "moderate" temperatures from 190 to 200 degrees Celsius.

Filament spools for metal 3D printing, in this case from SteelFill and CopperFill colorFabb (Steel and Bronze), Ancient Bronze (Ancient Bronze) from Formfutura

Here are the key points about metal printing at home

- Get a unique metal surface and look

- Ideal for jewelry, figurines, household utensils, replicas

- Durability

- Objects are not flexible (depends on structure)

- Objects don't dissolve

- Not considered food safe

- Typical print temperature: 195 - 220°C

- Extremely low shrinkage on cooling

- Table heating is not required

- Printing complexity is high, fine tuning of nozzle temperature, feed rate, post-processing is required

Preparing Your Home Printer for Metal 3D Printing

Since getting metal 3D prints is more difficult than usual, you may need to upgrade your 3D printer nozzle, especially if it's a printer. entry level. The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

You will also need to take care of the final finishing of the surface (cleaning, grinding, lubricating, waxing or priming) so that the printed metal object shines as it should.

How much is metal filament for 3D printing?

And how much is metal filament for 3D printing? - you ask. Here are some examples:

- A 500-gram BFSteel and BFBronse coil from Bestfilament costs 1600-1800 ₽

- ColorFabb's 750 gram Bronzefill Coil is $56.36

- ColorFabb's 750 gram Copperfill Coil is $56.36

- Protopasta's Polishable Stainless Steel PLA Composite costs $56 for 56 grams

- Protopasta's Rustable Magnetic Iron PLA Composite is $34.99 for 500 grams.

Metal 3D printing in industry

But what if you need a higher quality result, or even an all-metal 3D print? Should a real "metal" 3D printer be purchased for business needs? We wouldn't recommend it - unless you're going to be doing it every day. A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

Reducing the cost of metal 3D printing

If you are not going to open a metal 3D printing business, but you still need a metal part professionally made on a 3D printer, it is better to contact the appropriate company that provides such services. 3D printing services like Shapeways, Sculpteo and iMaterialise offer direct metal printing.

Currently, when 3D printing, they work with the following metal materials:

- aluminum

- steel

- brass

- bronze

- Sterling silver

- gold

- platinum

- titanium

If you are a jeweler, you can also order wax models to be cast in precious metals.

If we talk about wax models, then in most cases it is they (with subsequent melting) that are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in firms that offer such services.

The reason 3D printing is so popular with large companies is that it can be used to build fully automated lines that produce “topologically optimized” parts. This means that it is possible to fine-tune the raw materials and make the components thicker only if they must withstand heavy loads. In general, the mass of parts is significantly reduced, while their structural integrity is preserved. And this is not the only advantage of this technology. In some cases, the product turns out to be significantly cheaper and affordable for almost everyone.

Please keep in mind that metal 3D printing requires special CAD programs for modeling. It is worth paying attention to the recommendations Shapeways - 3D printing metal guidelines. To delve further into the topic, check out Statasys’ information on related 3D printers and the nuances of metal 3D printing.

Here are some examples of Benchy test model pricing for metal 3D printing:

- Metal plastic: $22,44 (former alumide, PLA with aluminium)

- Stainless steel: $83,75 (clad, polished)

- Bronze: $299,91 (solid, polished)

- Silver: $713,47 (solid, mirror polished)

- Gold: $87,75 (gold plated, polished)

- Gold: $12,540(solid, 18k gold)

- Platinum: $27,314(solid, polished)

As you might expect, prices for solid metal 3D printing are quite high.

Metal 3D printing. Applications

GE LEAP aircraft engine parts 3D printed at the Avio Aero factory (Photo: GE)

GE LEAP aircraft engine parts 3D printed at the Avio Aero factory (Photo: GE)

There are several industries that are already using 3D printers to make everyday objects - you may not even know that these objects are printed.

- The most common case is surgical and dental implants, which in this design are now considered the best option for patients. Reason: they can be tailored to individual needs.

- Another industry is jewelry. Here, most manufacturers have abandoned resin 3D printing and wax casting, switching directly to metal 3D printing.

- In addition, the aerospace industry is becoming more and more dependent on 3D printed metal objects. The Italian company Ge-AvioAero was the first to do all-metal 3D printing. It manufactures components for LEAP aircraft engines.

- Another industry targeting metal 3D printing is the automotive industry. BMW, Audi, FCA are seriously considering this technology, not only for prototyping (3D printing has been used for this for quite some time), but also for making real parts.

Before metal 3D printing really takes off, however, there are some hurdles to overcome. And first of all, this is a high price, which cannot be made lower than during molding. Another problem is the low production speed.

3D metal printing. Technologies

![]()

Most metal 3D printing processes start with an "atomized" powder

You can talk a lot about "metal" 3D printers, but their main problems remain the same as for any other 3D printers: software and hardware limitations, material optimization and multimateriality. We will not talk much about the software, we will only say that most of the major specialized software companies, such as Autodesk, SolidWorks and solidThinking, try to emphasize as much as possible the fact that any shape can be obtained as a result of the metal 3D printing process.

In general, metal printed parts can be as durable as parts made from traditional processes. Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

3D printed metal may have different resolutions. At the highest resolution, the layer thickness is 0.0008 - 0.0012" and the X/Y resolution is 0.012 - 0.016". The minimum hole diameter is 0.035 - 0.045".

Let's, however, consider what metal 3D printing technologies are.

Metal 3D printing process #1:

The metal 3D printing process used by most relevant large companies today is called Powder Bed Fusion. This name indicates that some source of energy (a laser or other energy beam) melts an "atomized" powder (i.e., a metal powder that is carefully ground into spherical particles), resulting in layers of a printed object.

There are eight major manufacturers of metal 3D printers in the world that already use this technology; while we are talking here, there are more and more such companies. Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Metal 3D printing process #2:

With ExOne 3DP technology, metal objects are printed by binding the powder before it is fired in a forge (photo: ExOne)

With ExOne 3DP technology, metal objects are printed by binding the powder before it is fired in a forge (photo: ExOne)

Another professional approach that also uses a powder base is called Binder Jetting. In this case, the layers are formed by gluing metal particles together and then sintering (or fusing) them in a high-temperature furnace, just like it is done with ceramics.

Another option, which is also similar to working with ceramics, is mixing metal powder into metal paste. A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i.e. in the mountains

This approach is taken by the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

Metal 3D printing process #3:

It may seem that the only 3D printing process that is left out of the metal work is layer-by-layer deposition. This is not entirely true. Of course, on some desktop device, simply fusing metal threads onto the base will not work. However, very large steel companies can do it. And they do. There are two options for working with "metal surfacing".

One is called DED (Directed Energy Deposition) or Laser Cladding (laser cladding). Here, a laser beam is used to melt the metal powder, which is slowly released and solidifies as a layer, and the powder is fed using a robotic arm.

Usually the whole process takes place in a closed chamber, but in the MX3D project, the construction of a full-sized bridge used the techniques of familiar 3D printing. Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military.

Metal 3D printing. Metals

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing, it is definitely one of the most versatile, strong and light. Titanium is used both in the melting process in a preformed layer and in the process of spraying a binder and is used mainly in the medical industry (for the manufacture of personal prostheses), as well as in the aerospace industry, automotive and machine tools (for the manufacture of parts and prototypes). But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment.

Stainless steel is one of the cheapest metals for 3D printing. At the same time, it is very durable and can be used in a wide range of manufacturing and even artistic and design applications. The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

![]()

Inconel is a superalloy manufactured by Special Metals Corporation, its registered trademark. The alloy consists mainly of nickel and chromium and is very heat resistant. Therefore, it is used in the oil, chemical and aerospace (for black boxes) industries.

Due to its lightness and versatility, aluminum is very popular in 3D printing. Aluminum alloys are commonly used.

This alloy has a very high specific strength (ie, strength divided by density, which generally indicates the force required per unit area to break). It is most commonly used in the manufacture of turbines, dental and orthopedic implants, where 3D printing has become the dominant technology.

With few exceptions, copper and bronze are used in wax melting processes, rarely in layer melting. The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

Iron, incl. magnetic, also mainly used as an additive to PLA-based filaments, which are produced, for example, by ProtoPasta and TreeD.

Most preformed melt companies can 3D print precious metals such as gold, silver and platinum. Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics.

Metal 3D printing. Printers

Don't even hesitate - the purchase of a metal 3D printer will not go unnoticed for your budget. It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

#1 metal 3D printer:

Sciaky EBAM 300 - metal filament printing

If you need to print really large metal structures, Sciaky's EBAM technology is your best bet. By order, the device can be built in almost any size. This technique is used mainly in the aerospace industry and the military.

The largest of Sciaky's serial printers is the EBAM 300. It prints objects in a volume of 5791 × 1219 × 1219 mm.

The company claims that the EBAM 300 is also one of the fastest commercially available industrial 3D printers. A three-meter-sized titanium part for an aircraft is printed on it in 48 hours, while the material consumption is about 7 kg per hour. In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer.

Sciaky's unique technology uses a high-energy electron beam to melt a 3mm titanium rod at a standard melting rate of 3 to 9 kg per hour.

Metal 3D printer #2:

Fabrisonic UAM - ultrasonic 3D printing

Another way to print large metal parts is Fabrisonic's UAM (Ultrasound Additive Manufacturing Technology). The devices of this company are three-axis CNC cutters, to which welding heads are added for the additivity of the process.

The metal layers are first cut and then ultrasonically welded. Most big printer Fabrisonic 7200 operates in a volume of 2 x 2 x 1.5 m.

Metal 3D printer #3:

The largest metal powder 3D printer on the market is the Concept Laser XLine 1000. It has a modeling volume of 630 × 400 × 500 mm and is the size of a house.

Its German company, one of the main suppliers of 3D printers for aerospace giants like Airbus, recently introduced a new machine, the Xline 2000.

This equipment uses two lasers, and the working volume is 800 × 400 × 500 mm. Uses LaserCUSING laser technology (a variant of selective laser fusion) from Concept Laser, which allows you to print alloys of steel, aluminum, nickel, titanium, precious metals and even some pure substances (titanium and stainless steel).

Metal 3D printing. Services

There are more than 100 companies worldwide offering metal 3D printing services. We list the most popular services for consumer needs.

#1 Metal 3D Printing Service: Shapeways

The world's most popular 3D printing service, Shapeways, offers two types of services. As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a marketplace for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

Metals for 3D printing: aluminium, brass, bronze, gold, platinum, precious metal plating, silver, steel. There are also wax molds for jewelry purposes.

Metal 3D Printing Service #2: Sculpteo

Like Shapeways and i.materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them for production in a wide range of materials. Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help to identify flaws in the design and choose the right material for the project.

Metals for 3D printing: alumid (plastic with aluminum particles), brass, silver.

Metal 3D Printing Service #3: iMaterialise

Materialize is a company that works with industrial clients to prototype 3D printed products. For ordinary users and designers Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.materalise online store or by embedding some code into their website.

Metals for 3D printing: alumide (plastic with aluminum powder), brass, bronze, copper, gold, silver, steel, titanium.

Metal 3D Printing Service #4: 3D Hubs

Through 3D Hubs, you can search for individuals and businesses that offer 3D printing services in your area, upload STL files (which are immediately assessed for defects), and contact service providers directly to get the job done. The online 3D printing service also allows you to sort offers by materials, customer rating, distance and many other parameters. Whatever object you wish to print, chances are there is someone nearby who can do it. A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

Metals for 3D printing: aluminium, bronze, cobalt-chromium, stainless steel, titanium.

One of the promising areas that many people are now paying attention to is 3D metal printing, the price of which is affordable. Arguing the popularity of this method is quite simple. The fact is that at present it is one of the most promising industries, which will soon be able to replace prototyping options. A big plus is the material that is used to create models. It is possible that in the near future such printers will be located at bases and construction sites, but for now it is worth understanding their types and the principle of operation.

A 3D printer, which produces metal printing according to technologies, can produce almost any figure for which there is a three-dimensional model.

How is the work going?

Now 3D printing with steel is most often carried out, it occurs due to the fact that both laser and inkjet printers. In both cases, the mass is applied layer by layer, thanks to which the desired object will be created. After that, a sufficiently solid model will "grow" on a special platform for building. Selective laser sintering, electron beam melting and deposition inkjet modeling are currently highlighted. Each of these options will be different and are best used in certain industries.

Of course, models that are made of metal, and not of plastic, will be stronger and have more design solutions. In addition, in the future, the created parts can be used in practice without any problems, put into production as a trial version. We can say that 3D printing with titanium or steel can speed up many processes in production, help to avoid a large number of errors.

What will be the price of the product?

Most often, the cost of the model will be based on 3 indicators:

- Options. This includes dimensions and volume.

- The speed of the ordered product.

- The type of metal that is used to make parts, as well as the number of treatments after creation.

Material prices may vary. It is best to check directly with the company, but usually one cubic centimeter of stainless steel costs about 550 rubles. Standard time to create a model can be from 15 days to 1 month.

At the request of the customer, titanium, stainless or carbon steel can be used. Individual alloys are also used, the composition of which is announced to specialists. 3D printing of metal parts is also carried out abroad.