- Recovery Mode

3D printing in construction

Construction 3D printers are engineering devices that create structural elements of buildings, small architectural forms or entire structures layer by layer - just like any 3D printer prints objects from plastic or other material.

Architects and contractors around the world are beginning to build the first 3D residential buildings, including houses and apartment buildings. Not only could this revolutionize the construction industry, but the less expensive process could also impact housing affordability. Lower material use and lower labor costs create a less expensive construction method, which in turn can create low-cost housing.

In addition to making housing more affordable, many architects are also hoping that 3D printing will increase their ability to customize homes and buildings. Each layer is then sprayed with water to strengthen the structure. Faster and more accurate design - a 3D printer transfers a digital model into a physical one; errors that occur can only be caused by errors in the digital model or the materials used. Reduced waste generation - components can be custom printed during construction; those not used can be recycled. This technological process which are you considering for the future of your business?

A construction 3D printer differs from a conventional 3D printer in the material used and dimensions - its working surface is a section of a construction site or workshop, and it prints with a cement mixture.

There are also design differences due to the specifics of the material - in particular, in a construction 3D printer there is no need for a heating element. Such devices allow you to quickly and without unnecessary difficulties print objects of almost any given shape, which are simply impossible for conventional mass construction using standard mixtures.

Once your browser opens, scroll down to the Construction Business category. You can vote once per category once per Internet-enabled device. Thanks to its long robotic arm and crawler tracks, it is designed to work on the construction sites of the future. To prove his specialty, he recently printed the largest robot-built structure - in just 13 hours.

This isn't the first time engineers have tried to automate construction. Almost 100 years ago, Thomas Edison patented a system that would create concrete structures in one go. But until now, construction bots have mostly been used in labs and demonstrations.

Start

We are interested in any promising application of 3D printers, so as soon as information about the use of 3D printing in construction began to appear on the Internet, we quickly found people involved in this and agreed on cooperation. It was especially pleasant to learn that in Russia there are companies that are thoroughly involved in construction 3D printers and produce a very high-quality product.

They haven't broken into mainstream construction because people are still figuring out how to build an automated robot that is actually useful in the real world. Therefore, to create their ideal construction robot, the authors came up with a number of criteria. The robot would have to be able to use materials found on a construction site and possibly remove itself from the environment, such as ice or dirt. This would make it useful in remote areas and even on other planets such as Mars.

The robot must also be able to move independently. Otherwise, people will have to move it, which can be dangerous. But it probably shouldn't fly. Flying robots are too susceptible to being hit by wind or rain, and if they suddenly stop working, they won't just stop - they'll fall to the ground. A robot would need a nice long arm to lift heavy things, stretch long distances, and perform finely detailed tasks. And it had to be able to integrate into existing construction practices and use existing materials.

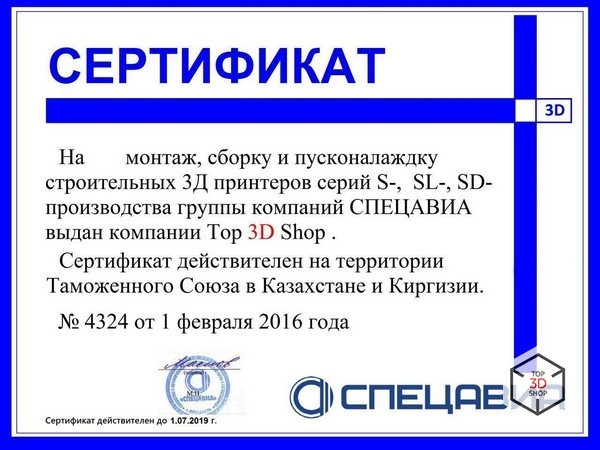

In Russia, the pioneer of 3D printing in commercial use was the company SpetsAvia. Its staff developed and tested a prototype of a construction 3D printing machine and carried out test printing.

Teamwork of construction robots

Dubbed a digital construction platform, their robot is basically a giant hydraulic arm that moves along crawler tracks. Attached to the end of the arm is a one-armed arm that can move more freely and is responsible for fine motor tasks. It can be equipped with a variety of tools, including a foam gun, a welding jig, a "thermoplastic extruder" that extrudes melted plastic, a glorified spray gun, and even a simple bucket.

We agreed on cooperation and sent a service engineer to Yaroslavl for training, where he learned a lot of useful things. The training program included, in particular:

D printer and house construction as complementary elements

The original robot chassis they used was powered by a diesel engine. But to make the bot more self-sufficient, the team equipped it with solar panels and battery packs to power the electric drive. Then they had to make sure it worked. Over the next two days, the robot created a sort of open-top igloo using expanding foam that sets up in just 30 seconds. The final structure was 12 feet tall with a diameter of almost 50 feet.

- A short introductory course on the interface and functionality of management software

- Instructions on the algorithm for working in the SheetCam program, which converts files into a layer-by-layer format that can be perceived by the printer

- Instructions on how to control the printer in the Mach 3 program, directly during the printing process

- Calibration - setting zero points in different areas of the printed field

- Adjusting the concrete supply during printing

- Instruction on the operation and maintenance of the mechanical part of the printer

- Troubleshooting

- Preparation of working mixtures

D-printing in construction

These aren't the most polished of homes, but for people exploring another planet it would be better than nothing. If this were an actual construction project, this foam would be used as a mold for the concrete. However, there are some big problems for the team. Given how quickly construction sites and environmental conditions can change, the robot will need to navigate better than it currently does and understand and respond to where it is in space and what's around it. This will mean equipping the robot with proximity sensors, searching for other machines or, most importantly, people.

First steps in practice

Having received the first order in this area, we sent our employee to the buyer - to Kazakhstan, to install the first S-6045 construction 3D printer and train the customer’s personnel to work with it.Before shipping the equipment, you must ensure that the packaging is secure. Transport companies do not always handle cargo with care; it is better not to take unnecessary risks - in our case, during transportation only a few contacts came loose, but this also cost nerves and several hours of time, as discussed below. If something breaks during transportation, the costs can be much higher.

Eventually, humans will still have to be around - the robots aren't smart enough, but they won't take over completely just yet. However, much remains to be done before this happens. Construction work appears to be safe - on this moment. This critical step between conceptual design and the first brick on a construction site helps architects explore the interaction of volumes and shapes, communicate design ideas, explore how a design looks from different perspectives, visualize light interactions and even the key selling phase of a design.

Back in the old days, and especially today with today's complex projects, manual architectural modeling requires skilled craftsmanship and huge amounts of time, so it was natural to move towards faster, more accurate and simple option. Questions then follow: Can architects and builders do more than just small-scale models with additive manufacturing techniques?

In the first days of the business trip, our employee checked the completeness of the delivered equipment, took measurements of the room to calculate the installation, agreed with the customer’s representatives on the location of the future printer, briefed them on the planned work, and began the installation.

As one of the pioneers of this technology, Dr. Behrokh Khoshnevis from the University of Southern California spent over 15 years developing his contour drawing system. Among the important advantages such as its complex shape capabilities and high speed Compared to traditional construction methods, such a system inherits one of the best characteristics of all 3D technologies: there is virtually no material wasted, which, coupled with its automatic nature, could mean more affordable housing when the technology fully matures and is widely used.

Markings were made for installation and holes were drilled in the floor for the racks.

After the preparatory work and installation of the racks, it was time to install the load-bearing beams. The structural elements are very heavy and such work requires several people, which is also better to agree on with the customer in advance, otherwise delays are inevitable. In the end, people were found and everything was done.

New building materials, faster construction, reduced waste

Although it is the only one with extraterrestrial goals, it is just one of several projects moving in the same direction. According to the company, this method allows them to save up to 60% of the materials typically needed for traditional construction methods and requires 80% less labor, resulting in more affordable housing, at least in theory.

Challenges for construction companies

Even if such claims are not true, there are still many questions that need to be asked of all existing print technology developers.Another difficulty that may arise when installing a construction 3D printer is an uneven floor. Without a flat surface, print quality is unlikely to be good. The obvious way out of this situation - leveling the floor - is hardly possible at the printer installation stage. There's simply no time for this.

It was just such a surprise, namely a significant tilt of the floor, that we discovered after leveling.

It was decided to weld frames from a steel profile that would compensate for the unevenness.

This also took some time. In the end, the required profile was delivered, properly cut and welded.

Currently, none of these systems can handle core elements of the conventional building construction process, such as electrical services, plumbing, doors, windows, millwork and trim. All of which still require a significant amount of time and manual labor to be installed in the 3D printed shell using conventional methods, reducing the overall time and cost savings of using a significantly more complex system. Additionally, research on structural stability against earthquakes and winds still needs to be done before anyone can live comfortably in a 3D printed house.

To install the leveling frames, the already mounted racks with beams had to be lifted by a construction crane.

The calipers and bearings for them were mounted, after which it was the turn of the portal beam. Here again the help of a construction crane came in handy, but I had to tinker with it - due to the configuration of the room and the design features of the crane, I had to go up to the ceiling and turn off the limit switches that limited its mobility. The ceiling there is about 15 meters.

Additionally, there are some structures that may require less capability, which we can achieve with our current technology. According to their website, they cleverly took a commercially available industrial robot, equipped it with an advanced welding machine, and coded their brains to create amazingly amazing metal structures without any supporting material, simply building them in the air. Feats like the bridge they're about to build in Amsterdam are nothing short of impressive, but also simpler than printing entire functional buildings.

Installation of the extruder boom and the eccentrics that control it took some time - the welds on the boom itself interfered with the connection with the docking grooves of the platform. I had to level it using a grinder.

On final stage All connections were tightened, an extruder hopper and an optional part of the structure - a concrete mixer - were installed.

Connecting the power and control circuits did not immediately go smoothly. However, SpetsAvia responded promptly to the letter of request sent to Yaroslavl, providing all the necessary recommendations for connection, despite the end of the working day.

General technological process

In fact, it wouldn't be much of a surprise that the future technologies that will allow us to print more, safer and faster will be an integration of all the developments that are happening today. In any case, it will definitely be interesting. While we still cannot offer you a real-size 3D printed house, we can print your architectural model in both plastic and multi-color material for a hyper-realistic look to your project.

BetAbram P1, P2 and P3, Slovenia

Transformed that almost anything can be done. This has disrupted manufacturing and manufacturing, allowing prototypes to be created in minutes using a variety of printing materials to create and test products from food to fashion. The rapid production of these products helps cater to the needs of a growing population.

During the inspection, it turned out that the contacts on one of the system boards came loose during transportation. After restoring the contacts everything worked.

After connecting and checking the connection, grease nipples were installed on all bearings, protective shields for the boom eccentrics and complete plates, and the installation itself was completed.

One industry in particular that has felt the strain of demographic growth is construction. Their first designs were modest, one-size-fits-all apartments built by combining individual rooms. Their printer is so large that it can print entire structures in one job, rather than having to create and combine components.

One of the firm's goals is to use the technology in rebuilding after destruction caused by disasters such as earthquakes, which often affect China. The printing process combines layer upon layer of concrete to create complex architectural structures that cannot be achieved with conventional methods. Their main goal is to create a printer large enough to print entire houses. This contributes to changing attitudes towards the industry. This is literally true, as with the help of an advanced six-axis industrial robot, they can print structures in mid-air.

Next - installing and configuring the software, checking the functionality. Installation of a backing for hanging wires connecting moving parts - it is not included in the delivery package, but we do our best to accommodate our customers.

Training customer personnel in handling the printer during the trial run.

The customer decided to test a mixture of his own authorship, contrary to our recommendations. Well, the owner is a gentleman. The solution, quite expectedly, began to creep. However, the printer itself works normally and we have no complaints.

In the process of training client personnel to work with software, we wanted to demonstrate how a 3D printer works with the right mixture, but we didn't have the ingredients for a new mixture.

By the way, about mixtures:

Staff training and facility delivery were as positive as possible. The customer's representatives were completely satisfied with the supplied and installed equipment and were pleased with the cooperation.

It was a rewarding experience. We have identified several rakes for ourselves that we will not step on a second time - and this will make further work more pleasant and efficient. Undoubtedly, construction 3D printing equipment is a very interesting field of activity, both in terms of the results obtained, and in the fact that it requires maximum ingenuity and a non-standard approach from those involved in it.

Want more interesting news from the world of 3D technology?

Price: 720,000 rub.

Description Characteristics

The S-4063 printer is the first of the developed small-format printers that allows you to print various elements for houses, gazebos, and all kinds of landscape buildings with concrete.

- The S-4063 printer is the first of the developed small-format printers that allows you to print various elements for houses, gazebos, and all kinds of landscape buildings with concrete.

- The S-4063 printer is equipped with powerful drives that allow you to quickly and accurately move the print head with storage from 18 to 32 liters. Stepper motors with helical gearboxes and other components are for professional equipment and are designed for industrial use.

- The printer is not mass-produced. It served as a prototype for the creation of the next model in the line of S series printers - the S-6043 and S-6044 printers.

- The S-4063 printer works with finely dispersed mixtures. The thickness of the printed layer is less than in other models.

- Can be made to order.

Dimensions

| Manufacturer | JSC "SPETSAVIA" |

| Manufacturer country | Russia |

| type of drive | |

| Type | Construction 3D printer |

| Purpose | Printing building elements, small forms up to 18 m2 |

| Working speed, m/min | 8 |

| Working area, mm | 3500x5200x1000 |

| Equipment | |

| 12 m/min 1 mm | |

| Power consumption, kW | 1,3 |

| 8 x 20 | |

| 0,08 | |

| Guarantee | 12 months |

CONSTRUCTION PRINTER THREE-DIMENSIONAL PRINTING (3D) S-6043

Price: 890,000 rub.

Description Characteristics

- The printer allows you to print concrete elements for a house, a gazebo, a small garage, all kinds of landscape buildings, a pond, a children's playground or a swimming pool!

- It is also suitable for printing stoves, fireplaces, barbecues, barbecues and other fire-resistant products using koalin mixtures. At the same time, the printing process itself is no different from printing, for example, garden interior items with cement compounds.

- Our printers are reliable and repairable. All components are industrially produced and designed for heavy-duty professional use, which opens up new opportunities for small businesses in construction and related fields.

- Without exception, all printers undergo control assembly at the enterprise. The equipment is delivered to you in a debugged condition, tested for performance.

- Our company’s specialists will assemble and launch your equipment and teach you how to model and control the printer.

- The S-6043 printer prints with standard 500 series cement-based compounds, i.e. what is freely available on any construction market. You can use mixtures with mineral additives and fiberglass. The operating instructions contain technological regulations for the mixture, according to which it will not be difficult to prepare the necessary concrete for printing.

Dimensions

Technical characteristics of 3D printers

| Manufacturer | JSC "SPETSAVIA" |

| Manufacturer country | Russia |

| type of drive | Stepper motors with helical gearboxes |

| Type | Construction 3D printer |

| Purpose | |

| Working speed, m/min | 9 |

| Working area, mm | 3500x3600x1000 |

| Equipment | Printer, monoblock, industrial keyboard, control cabinet. |

| Positioning speed, Positioning accuracy | 12 m/min 2 mm |

| Power consumption, kW | 1,5 |

| Printed layer size, mm (height, width) | 10 x 30 |

| Concrete consumption, m3 per 1 sq.m of wall with 4-layer printing | 0,12 |

| Guarantee | 12 months |

CONSTRUCTION PRINTER THREE-DIMENSIONAL PRINTING (3D) S-6044

Price: 860,000 rub.

Description Characteristics

The S-6044 printer is a new model of small-format printers of the S series, which allows you to print small forms with concrete measuring about 12 cubic meters, that is, various elements for residential buildings, gazebos, all kinds of landscape buildings, a small pond, a children's playground or a swimming pool! It is also suitable for printing stoves, fireplaces, barbecues, barbecues and other fire-resistant products using koalin mixtures.

- Our printers are reliable and repairable. All components are industrially produced and designed for heavy-duty professional use, which opens up new opportunities for small businesses in construction and related fields. The equipment warranty is 12 months.

- When configuring the printer, the customer’s wishes are taken into account, incl. The printer design can be mounted on walls, on stands, or a combination.

- The S-6044 printer prints with standard 500 series cement-based compounds, i.e. what is freely available on any construction market. You can use mixtures with mineral additives and fiberglass. The operating instructions contain technological regulations for the mixture, according to which it will not be difficult to prepare the necessary concrete for printing.

Dimensions

Technical characteristics of 3D printers

| Manufacturer | JSC "SPETSAVIA" |

| Manufacturer country | Russia |

| type of drive | Stepper motors with helical gearboxes |

| Type | Construction 3D printer |

| Purpose | Printing building elements, small forms up to 12.6 m2 |

| Working speed, m/min | 9 |

| Working area, mm | 3500x3600x1000 |

| Equipment | Printer, monoblock, industrial keyboard, control cabinet. |

| Positioning speed, Positioning accuracy | 12 m/min 2 mm |

| Power consumption, kW | 1,5 |

| Printed layer size, mm (height, width) | 10 x 30 |

| Concrete consumption, m3 per 1 sq.m of wall with 4-layer printing | 0,12 |

| Guarantee | 12 months |

CONSTRUCTION PRINTER THREE-DIMENSIONAL PRINTING (3D) S-6045

Price: RUB 1,788,000

Description Characteristics

The S-6045 printer is an improved model of small-format S series printers, developed on the basis of the S-6043, which allows printing with concrete of various compositions, including standard cement-based compositions of the 500 series, i.e. what is freely available on any construction market and use mixtures with mineral additives and fiberglass. Traditionally, our company deals with industrial CNC equipment. The new model of the S-6045 printer with more capabilities and expanded equipment has been accepted for mass production.

The use of 3D printers in construction is a very promising area of activity. Despite the novelty and uniqueness, there are more and more people who want to build using the now popular 3D printing technology. 3D printing allows you to produce products of various complex shapes with minimal time and material costs. Printing building elements with complex patterns is an easy task for such equipment. For creative people, a 3D construction printer is simply a godsend that can bring a lot of new emotions! Turrets, arches, columns printed on a printer organically fit into the architecture of houses. Any landscape will be decorated with creative forms of various benches and gazebos.

- The S-6045 printer is an improved model of small-format S series printers, developed on the basis of the S-6043, which allows printing with concrete of various compositions, including standard cement-based compositions of the 500 series, i.e. what is freely available on any construction market and use mixtures with mineral additives and fiberglass.

- The printer is suitable for printing small forms measuring approximately 12 cubic meters.

- Printer components (rail guides and stepper motors) are made in Europe.

- In the basic configuration, the printer is equipped with three print heads designed for printing with different compositions. Set includes mortar stirrer and pressure washer

- When configuring the printer, the customer’s wishes are taken into account, incl. The printer design can be mounted on walls, on stands, or a combination.

- Without exception, all printers undergo control assembly at the enterprise. The equipment is delivered to you in a debugged condition, tested for performance. Our company’s specialists will assemble and launch your equipment and teach you how to model and control the printer.

- The equipment warranty is 12 months.

- The operating instructions contain technological regulations for the mixture. The software comes with a library of ready-made files with various landscape design elements and building elements.

Dimensions

Technical characteristics of 3D printers

| Manufacturer | JSC "SPETSAVIA" |

| Manufacturer country | Russia |

| type of drive | Stepper motors with helical gearboxes |

| Type | Construction 3D printer |

| Purpose | Printing building elements, small forms up to 12.6 m2 |

| Working speed, m/min | 9 |

| Working area, mm | 3500x3600x1000 |

| Equipment | Printer, monoblock, industrial keyboard, control cabinet. |

| Positioning speed, Positioning accuracy | 12 m/min 2 mm |

| Power consumption, kW | 1,5 |

| Printed layer size, mm (height, width) | 8 x 20, 10 x 30 |

| Manufacturer | JSC "SPETSAVIA" |

| Manufacturer country | Russia |

| type of drive | Stepper motors with helical gearboxes |

| Type | Construction 3D printer |

| Purpose | Printing building elements, small forms up to 110 m2 |

| Working speed, m/min | 9 |

| Working area, mm | 10x11x2.7 |

| Equipment | Printer, monoblock, industrial keyboard, control cabinet. |

| Positioning speed, Positioning accuracy | 12 m/min 2 mm |

| Power consumption, kW | 3,5 |

| Printed layer size, mm (height, width) | 10 x 30 |

| Concrete consumption, m3 per 1 sq.m of wall with 4-layer printing | 0,12 |

| Guarantee | 12 months |