Testing methodology laser printers

To check the print quality of printers, our laboratory has developed a special set of tests used in various combinations, depending on the type and class of printer.

For testing monochrome and color laser printers, the complex looks like this:

1. Print speed. Where appropriate, the printer's print speed is measured using the Xerox recommended 5% paper coverage sample (PDF sample ).

A job consisting of several copies of the above document is sent to the printer (to increase accuracy, as a rule, 2N+1 or 3N +1 copies, where N is the printing speed declared by the manufacturer), then the time of the first print is subtracted from the result and then the “net” printing speed is calculated .

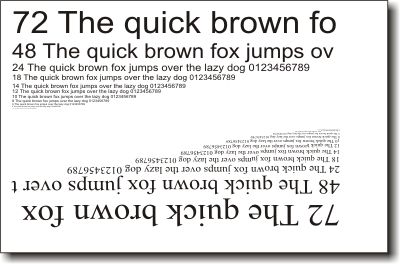

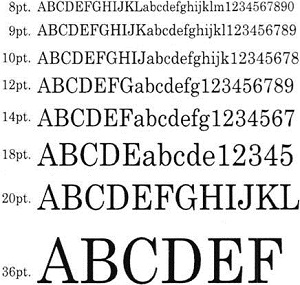

2. A set of control fonts. Original file in vector CDR format Corel programs Draw can be obtained

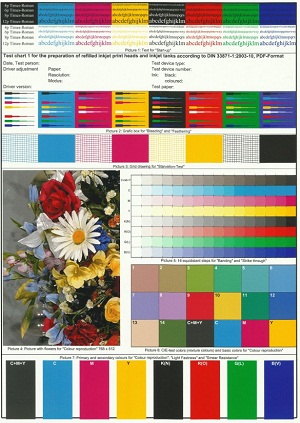

3. Universal test set of vector elements. Especially for testing color laser printers, a 512-step fill is used in raster gradient modules of each color. Radial lines are used to check the quality of combining yellow (Yellow) and turquoise (Cyan) colors for the synthesis of green shades. In the center of the 90-point star there is a 1 pt thick spiral. The original file in vector CDR format of the Corel Draw program can be obtained

Printer testing method

The testing methodology for different types of printers differs due to several factors. But during the testing process, experts still adhere to certain general standards and a more or less uniform approach. One could even say that over several decades, which became a period of rapid development of the printing market, a list of rules for conducting printer testing techniques was formed. True, each type of printing device has its own specific rules. For example, the testing process for color laser and inkjet printers is somewhat different from testing dot-matrix or dye-sublimation printers.

The greatest importance in the process of testing printers is given to the quality characteristics of printing and the performance of the printing device. After all, these are the indicators that concern the potential buyer the most. Of course, along with print quality and performance, the user is also interested in the cost of the printer itself and the costs associated with its maintenance. IN Lately When testing a printer, attempts are made to characterize the printing device in terms of whether the print quality provided corresponds to the stated cost.

Regardless of what type of printer is being tested, be sure to pay attention to the following parameters:

1. specifications printer, its hardware capabilities;

2. the printing technology used, its advantages and disadvantages;

3. design of the printing device body, quality of its execution;

4. printer software, availability useful programs and their effectiveness;

5. Printer equipment upon delivery.

Checking the printer's print quality

Print quality depends on many factors, and when testing a printer, it will be determined depending on the printing technology used by the printer, as well as depending on the thickness of the paper, ink and software printer.

It is the connection of all these factors that makes it possible to make a final “verdict” on the quality characteristics of the printer being tested.

When assessing print quality, special attention should be paid to the level of color rendering and the ability to accurately convey the halftones of the original image. Very often, the transmission of halftones depends on whether the printer is able to provide high-quality and uniform shading of various areas, especially light areas of the image.

In many ways, print quality also depends on the resolution of the printer, that is, the factor that affects the level of printing of small image details. In this regard, it is worth noting that in most cases, the print resolution declared by the manufacturer does not correspond to the real state of affairs, and real indicators can only be discovered during testing of the printer.

Basic methods for assessing print quality

The procedure for checking the quality of a print involves a subjective and objective assessment of the image made by the printer.

Subjective assessment of a print involves visually examining the print to determine print defects that are visible to the naked eye.

An objective assessment of a print involves a number of more complex procedures aimed at identifying printing defects. In the process of objective assessment of a print, the test image is first placed in a reference scanner, after which it is converted into an electronic version. Then the difference between the original and the digital version of the photo is determined. This is done using special software that allows you to record RGB indicators from special “dies”. When digitizing an image, a scanner may, of course, allow some error. To prevent this, the scanner is calibrated before testing.

In case of testing black and white printers The procedure for assessing print quality is greatly simplified, since the study of color characteristics is not required in this case.

Checking the Printer Print Speed

All manufacturing companies in the documentation included with the printer indicate such a printing characteristic as its speed. This “value” is measured in pages per minute, and it refers to different modes printer operation.

But you should not unconditionally trust the specified data on the printing speed of a printer, since you cannot be sure that when measuring the speed indicators of their printer models, all manufacturers use the same reference documents.

Therefore, if you need to compare the speed performance of printers from different brands in order to decide on the device you need, it is best to trust the results of independent testing conducted in good laboratories. Independent testing involves using the same templates to test the print speed of printers belonging to different brands. It is this data that will allow you to more or less objectively compare the speed characteristics of printers.

Printer printing speed is tested using electronic A4 format models of three various types. The first layout is 1 black and white page with text. The second layout is 1 page with text and graphic elements. The third layout is 1 page with a color photo, which is printed on high-quality photo paper in maximum quality print.

When printing all three types of test pages, the countdown time runs from the moment printing starts until the page is completely printed.

Main types of printer tests

Basic printer tests include tests that subsequently allow comparison of print quality and speed. various models printers.

To make it more convenient to compare the characteristics of printers with different print formats (for example, A4 and A3), paper of the same size is used during testing for such printers.

There are only seven main printer tests:

1. Test to determine the quality and speed characteristics of color printers. Test print carried out on office paper and high quality photo paper.

2. Test to determine the quality characteristics of black and white printing. Test printing is carried out on A4 office paper.

3. Test to determine the speed characteristics of black and white printing. Test printing is carried out on A4 office paper.

4. Test to determine the speed characteristics of mixed printing, which consists of elements of text, color and black and white graphics. Test printing is carried out on A4 office paper.

5. Test to determine the resolution of black and white printing. Test printing is carried out on A4 office paper.

6. Test to determine the resolution of color printing. Test printing is carried out on A4 office paper.

7. Ink test to determine its resistance to moisture. Testing is carried out using damp cotton wool and only after the print has dried.

Additional printer tests

In addition to the seven main tests for printers, which allow you to analyze the level of performance of the printing device of its basic functions, there are additional methods for testing printers that are focused on the study and analysis of operating characteristics additional features printing device.

Additional tests for printers include the following:

- checking the quality and speed of printing on the surface of CDs;

- checking the quality and speed of printing on roll paper;

- checking the quality and speed of printing on thick media.

Additional testing for the printer is determined, first of all, by the presence of a particular function in the printing device.

How the printer is tested

The printer testing procedure begins with calibrating the device's print heads. This is necessary in order to ensure the highest level of print quality, color rendition, and detail printing available to the printer.

Some models of printing devices require the installation of additional cartridges to ensure high-quality printing. When testing in such cases, these cartridges are installed. This allows you to get more accurate results when testing.

Printing during testing is carried out with automatic installations print. However, quite often, especially if the printer supports a large number of printing modes, the testing process involves printing in all valid modes and analyzing its results.

The process of testing a printer is largely determined by the characteristics of the printing device being tested, its capabilities and functions.

Test template files for the printer

Five types of test pattern files are used to test the printer's print performance.

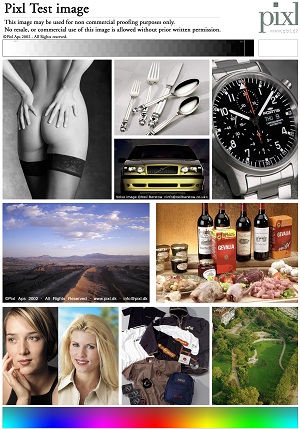

| The TF1 file is used when testing the quality and speed characteristics of color printers, as well as when analyzing the printer’s ability to produce high-quality color reproduction and the transmission of halftones and shades. Test printing of the TF1 file is carried out on office paper and high quality photo paper. File TF1 is a sheet of A4 paper on which a special target is depicted. This target contains several color drawings, as well as one black and white image. They help make a subjective assessment of the printer's print quality. In addition, this target contains a black triangle with gradient fill from 0% to 100% and a plate consisting of multi-colored sections. The 7 colors on a solid have different intensities and specific values in the RGB color space. This die serves to objectively assess the color rendering provided by a specific printer model. |

|

| To check the printer's black-and-white and color resolution, use the TF2 test file. When checking black and white print resolution, use office paper standard size A4. When checking color printing resolution, A4 photo paper is used. The TF2 test PDF file is an image consisting of several groups of elements. Each group of elements, in turn, is also divided into six separate parts. The elements of each group are numbered, and each subsequent element is slightly smaller in size than the previous one. A separate group element of the TF2 test file is a triangle. Half of the triangles in each group are vertical and the other half are vertical. In accordance with the quality of printing of each triangle by the printer, the resolution of the printer is determined. |

| The TF3 test template file is used to determine the quality of black and white text printing. To check the print quality using the TF3 file, standard A4 size office paper is used. The TF3 test file is a doc format document. This document consists of lines of various sizes typed various types fonts using in various ways styles. After printing this file, it becomes possible to determine the print level. The readability of small fonts also indicates the printer's resolution. The printer's black and white print speed is measured using the TF4 test file. During the testing process, standard A4 size office paper is used. |

The TF4 test file is a doc format document consisting of 1 page with text in 10 point New Roman font with single line spacing and standard style.

The period of time during which the printer is able to print this page, and is an indicator of monochrome printing speed.

The start of the time count in this case is the beginning of the printer's job execution. The countdown ends when the printed sheet leaves the printer and enters the tray.

The printer's mixed print speed is measured using the TF5 test file.

Mixed printing involves printing black and white and color text, as well as black and white and color graphics.

The TF5 test file is printed on a standard sheet of A4 office paper.

The TF5 test file is a doc format document with text and graphic content. The text in the TF5 test file is printed in Times New Roman font, 10 point. The text style is standard, the spacing between lines is single.

The graphics in the TF5 test file are represented by 2 images in the form of diagrams.

Checking the color quality of the printer

To measure the quality of a printer's color reproduction, methods similar to the principles of testing scanners are used.

The color quality testing process begins with digitizing a scanned TF1 test file. Digitization is carried out in color mode with the maximum resolution of the scanner. The resulting file is used to define RGB components in certain areas. This is done using graphic editor Adobe Photoshop as follows: in all areas of different brightness, the results of the transmission of seven colors (red, green, blue, yellow, black, purple, cyan) are recorded.

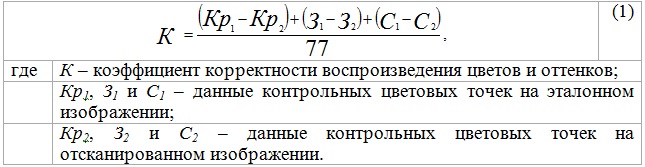

After this, all received data is entered into a color table, and using this data, the correctness of the printer’s reproduction of various colors and shades is determined. This coefficient is determined using the formula

K= ((Red1-Red2) + (Green1-Green2) + (Blue1+Blue2)) / 77, where

K – coefficient of correctness of color reproduction by the printer;

Red1, Green1, Blue1 – data of control color points on the reference image;

Red2, Green2, Blue2 – data of control color points in the scanned image.

As a result, the smaller the calculation result, the more accurate color rendering the printer provides.

Checking the color balance and halftone quality of the printer

November 27, 2012

In contact with

Classmates

To assess quality inkjet ink are used three types of test pages: TF1, TF2 and TF3.

TF1 test page used to test the quality of color inks. It allows you to analyze the ability of the ink to produce accurate color reproduction of shades and halftones.

|

|

|

|

Sample TF1 test files

The TF1 test page is printed on standard A4 paper. It is a collection of monochrome and color images, multi-colored square “dies” and areas with a gradient fill from zero to one hundred percent.

Using the TF1 test page, you can objectively evaluate both the color rendition of any one inkjet ink, and organize comparative testing several types of ink.

To determine the color rendering quality of inkjet inks, the resulting TF1 test pages are digitized using a color scanner. The resulting files are used to define RGB components in certain areas of the page. To do this, using the Adobe Photoshop graphic editor, the result of transmitting the primary ink colors is recorded, and the resulting data is entered into a color table. The resulting table allows you to determine the coefficient of correct reproduction of ink of various colors and shades. This coefficient is calculated using the formula:

Formula for determining the correctness coefficient

The lower the coefficient of correctness of reproduction of colors and shades, the more accurate color reproduction will be provided by inkjet printer ink.

The data obtained when checking the color rendering quality of inkjet ink allows us to construct a graph in which we plot the distance on the X-axis, and pixel values on the Y-axis. We connect the dots and get a single line, the dips and peaks on which indicate an unbalanced color rendering. If there are no dips or peaks, then the color rendition is balanced. The recommended range of deviations of RGB values should not exceed 255.

Next test page, which is used to evaluate the quality of inkjet inks, is the TF2 page.

TF2 test page

TF2 test page is a PDF file consisting of several groups of elements, which, in turn, include six independent parts, located vertically and horizontally. Groups of elements on the TF2 test page are numbered, with each previous element slightly larger than the next. The quality of printing of the smallest elements of the test page determines the resolution of inkjet ink.

TF2 test pages are used to test monochrome and color inks for inkjet printing. TF2 pages are printed on A4 paper. In this case, when testing monochrome inks, standard office paper is used, and when testing color inks, photo paper is used.

The third type of test pages are TF3 files, used to determine the quality of black monochrome ink.

TF3 test page

TF3 test page is a document in “doc” format, consisting of many lines of the same type, printed in fonts of various sizes. Test pages like TF3 can be printed either in one font or in different groups of fonts. Their use allows you to determine the print quality text documents, drawing of small letters and numbers, depth of black color when filling characters. The legibility of the smallest fonts indicates the quality and high resolution of the image obtained using the tested inkjet inks.

The TF3 test page is printed on regular A4 office paper.

November 27, 2012

In contact with

Comprehensive methodology for testing printers

Introduction

Most often, people purchase printers for specific tasks. Both an advanced digital photographer with high quality requirements and a caring parent, when choosing an inexpensive printer “for study” for their child, although vaguely, formulate the quality characteristics of the device. Therefore, when developing this technique, we proceeded primarily from the possible areas of application of each specific model printing device.

To eliminate pointless testing of printers in all possible (and innumerably multiple) combinations of applications, drivers, operating modes and settings, we start primarily from several general types of printers, users who may need certain capabilities, and tasks specific to each printer . It follows from this that our goal is not to make, say, an inexpensive inkjet printer from the “under $100” category work under conditions more suitable for a powerful laser printer with its own PostScript interpreter.

1. Maximum print speed

This test shows the maximum speed of the printing mechanism. Multiple copies of a single-page PDF file are sent to the printer at a standard 5% page coverage. The number of copies launched corresponds to the number of copies per minute declared by the manufacturer + 1 copy. Timing begins immediately after the printer issues the first copy. This eliminates the dependence of the result on the power of the computer, the type of file, drivers, the printer interface and the speed of processing the job by the printer itself.

The test runs on all types of printers. The result is the number of ppm.

2. Print a multi-page document with illustrations

Unlike the previous test, which simulates the replication of a one-page document, this test shows the printing time of a simple 20-page document in PDF format containing small raster illustrations in RGB format and text typed in 10 point size. Printing is done from Adobe Reader 6.0; time is measured from the moment the document is launched for printing. Since the document size and type are not standardized, and the driver processing time for the job is measured, the result reflects the relative performance of a particular application-computer-printer connection. Configuration test bench is given in the appendix.

The test runs on all types of printers. The result is time in minutes, seconds.

3. Assessing the quality of font reproduction

This test allows you to evaluate the print quality of text material typed in serif and sans serif fonts (Times New Roman and Arial, respectively). Font sizes decrease from 72pt to 2pt.

If the printer does not support the PostScript language, a PDF file from Adobe Reader 6.0 is printed. However, if the manufacturer declares support for the PostScript standard, the test page is output to the printer directly from the Adobe InDesign CS layout package.

The test runs on all types of printers. The result is the minimum readable font size (size in points), the quality of printing of curved and inclined elements of letters. The readability of a font means maintaining the integrity of the main elements of the letters (the absence of “frozen” elements or breaks in the letters).

4. Printing a universal test strip

A special test page is designed in such a way as to clearly show the printer's capabilities. The following items are available for assessment:

- neutral density scale. Range 0-10% in 1% steps, 10-90% in 10% steps and 90-100% in 1% steps;

- color stretches CMYKRGB 100-0%;

- scales showing the minimum and maximum reproducible densities of CMYK inks. Minimum densities are numbers from 1 to 8, colored in their corresponding shades, on a white background (0%). Maximum densities are numbers from 92 to 99 with the corresponding coloring against a background of 100%. Each color has its own pair of scales;

- scale consisting of 100% RBGYMCK color dies;

- RYGCBM color stretch created by using Adobe Photoshop CS;

- text typed in font sizes from 4pt to 8pt (5-9 pt for decorative fonts) in styles: decorative, serif, sans serif. The options are: normal (black text on a white background), reversed (white text on a black background) and colored (text of different colors on a rich green background);

- scales that allow you to measure the maximum reproducible lineature. They are sets of concentric circles. Available values, in lines per inch: 60-80 in increments of 5 lpi, 80-170 in increments of 10 lpi;

- a set of scales that allow you to evaluate ink registration and printer calibration accuracy.

They are sets of longitudinal, transverse, oblique, wavy and intersecting lines of different colors.

All test elements are located on a solid gray background, which has no margins, which allows you to determine the actual printing field of the printer.

For printers that do not support PostScript, the document is printed in PDF format from Adobe Reader 6.0. For PostScript printers, printing is performed directly from the Adobe InDesign CS layout package. The printed strip is scanned, after which all parameters are evaluated.

The test runs on all types of printers. The result is the actual values of all parameters.

5. Assessment of color rendering quality

|

|

|

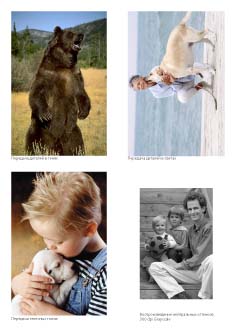

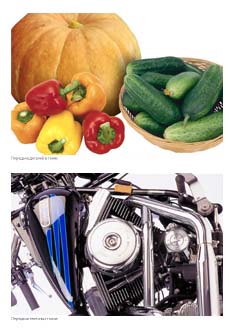

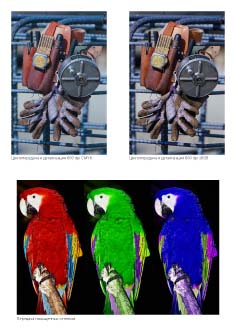

This test consists of a selection of photographs typical for assessing color fidelity, saturation and detail of images:

- photo of a brown bear. Dark wool with rich tonal variations allows you to appreciate the transmission of detail in the shadows;

- photograph of a woman with a dog. The dog's light fur, the woman's clothing and a fragment of the pier allow us to evaluate the transfer of details in the highlights;

- a photograph of a boy reveals the quality of the rendering of flesh tones;

- A black-and-white family photo with a wide range of tones helps evaluate the quality of the printer’s reproduction of the entire range of neutral shades;

- photography of vegetables. The colors of vegetables and greenery are very familiar to us all, therefore they are used by us as memorable colors and add their contribution to the assessment of color rendering;

- photo of a motorcycle engine. Metallic surfaces, highlights and harsh shadows show the printer's ability to produce high-contrast images with deep shadows and ringing reflections;

- photographs of instruments contain small details (texture of gloves, leather, scratched metal surfaces), warm, cold and neutral shades. In addition to checking the detail of the print, they help evaluate color separation algorithms. To this end, one of the photos is in CMYK space, and the other has an embedded sRGB color profile. The profile with which the image was converted into CMYK space is non-standard, created by us with our own hands. However, this profile has been repeatedly used in preparing images for high-quality sheetfed offset printing, and has proven its viability. The sRGB profile for an adjacent photo was not used by chance: an increasing number of devices (digital cameras, monitors, printers) declare full support for this space, so it becomes interesting to compare two different approaches: independent color separation in Photoshop or automatic color separation using the printer driver. Due to the fact that it makes no sense to print CMYK images on printers that do not support PostScript and then find fault with the quality of color rendering, for such devices this test only evaluates end-to-end sRGB profiling;

- photos of parrots are a synthetic test. The chest feathers of parrots contain a lot of detail, but at the same time they have a pronounced dominant color. Since in real life we rarely encounter such rich colors, this kind of stress test will be all the more revealing, revealing the borderline capabilities of the printer.

All images (except for photographs of instruments) have a resolution of 300dpi. Photo of tools - 600 dpi. For printers without PostScript support, a PDF file is used with RGB versions of images without embedded profiles (except for one of the photo tools). On PostScript printers, images in the CMYK version (except for one of the photographs of tools) are output directly from the layout package. For printers that support PDF format, a PDF file with CMYK versions of the images is sent (with the same exception as in the previous case). Photo printers are printed from the Adobe Photoshop CS package, each image (in the RGB version) is printed in a separate session. Also for photo printers, the time elapsed from the start of a print job to the output of the finished sheet is measured.

The test runs on all types of printers. The result is a visual assessment of printed samples and time in minutes, seconds.

6. Other

Along with the main characteristics of the printer, it is also important for the end user to know such parameters as the noise level of the printer, the ergonomics of the controls, the thoughtfulness of the design and even the aesthetic impression of the printer. appearance printer. We do not attach absolute importance to these parameters and evaluate them subjectively.

Paper used when testing laser printers:

- uncoated paper with a density of 200-220 g/m2.

Paper used when testing inkjet printers:

- plain, uncoated, office paper with a density of 80 g/m 2;

- universal glossy paper for inkjet printers from a third-party manufacturer;

- high quality glossy photo paper inkjet printers from a third party manufacturer;

- High-quality paper for photo printing on inkjet printers, recommended by the printer manufacturer.

There are three options for checking the color profile. The first method is to print black and white photographs - they must be black and white, without color impurities. You need to look after the ink has completely stabilized and with the source for which the color profile was ordered. The second way is to print photos and compare them with a calibrated monitor. It is possible that you will have to compare in paper simulation mode. Photoshop, Illustrator, InDesign, CorelDraw can do this. The third way is to print our test images and visually analyze their quality. The fact is that sometimes the printed image itself has a color shift, especially when shooting indoors. We tried to collect images without obvious color deviations.

Three blocks of images are presented:

- Checking RGB drivers. Printing from Windows using native printer drivers. RGB color profile.

- Checking Photolabs (wet printing). RGB pictures.

- Checking CMYK plotters running under RIP programs. CMYK test pictures.

RGB test images

|

|

|

|

|

|