The S90 series speaker systems (I personally saw the S90, S90i, S90B, S90D and S90F) are some of the coolest speakers you could find in the 90s. A 75GDN, an excellent speaker for those times, was used as a low-frequency link. But over time, everything changes. Now there are many speakers on the market that are several times superior to the 75GDN in sound quality. But good bourgeois acoustics cost at least 500 bucks, and this, compared to the current cost of the S90, is a cosmic amount. Here the question arises: “how to get good sound and not be left without panties after buying expensive speakers?” You can, of course, save for a long time, and then buy acoustics for 700 bucks and think: “what did I pay for?” (not always, of course, but it happens). There is no ideal sound, and tinkering with such speakers for the purpose of modifications is scary because of their price tag. Therefore, I propose a different way to obtain normal, high-quality sound, quite sufficient for indoor listening. (I want to make a reservation right away - those who want to redo the speakers just for fun shouldn’t even start - you won’t finish it anyway). I will not go into details of equalizing the frequency response, bass reflex calculations (hereinafter simply FI), etc., but will simply tell you how I remade my S-90B of the 87th year of production. I started by buying them for 70 USD. The S90 series acoustics have quite a lot of “ weak points " I tried to fix every one. The biggest drawback (both literally and figuratively) of them is the body - it has a small volume... and in general it is made like that - if only it was. The low frequencies in it boom a lot. Therefore, I decided to make a new case (when disassembling the old one, I first marked the polarity of the speakers, so as not to confuse them later). For the new case, plywood with a thickness of 22 mm is suitable. You can, of course, take a thicker one, but then the column will be larger and heavier. As a result, I got a case with dimensions of 350*360*1200 mm. and a working volume of 106 liters (excluding PAS, phase converter and all other internals). In principle, the size of the box can be made to any size - at the discretion of the designer, the main thing is that the volume fluctuates around 100 liters. When assembling, the following parameters must be observed: 1) the front or rear wall must be tilted inside the housing by 2-2.5 degrees so that “standing” low-frequency waves do not form inside. I tilted the back one, retreating from the top 5 cm from the vertical line. 2) you need to make stiffening ribs inside so that the column does not “inflate” (you need to make them so that you can then put a filter on the back wall). To do this, you can take a 25 block or make them from the same plywood. I placed the ribs in two places perpendicular to the side walls. They are made from plywood and “divide” the column into 3 parts. 3) during assembly, all joints must be carefully glued (with glue or sealant) and tightened well with furniture screws. The housing must be completely sealed, otherwise the sound will be distorted. I placed the screws at a distance of 15mm. from each other, and made their hats “hidden”. For gluing I used “Body 999” sealant 4) There should be no corners inside the column. I achieved this using wooden slats that resemble a baseboard. You can also use some kind of putty for this purpose. 5) you can coat the inside with varnish to get a better “reflective” effect, but I didn’t do this. So, when the future walls of the body are cut from a sheet of plywood (it’s better to saw on a machine, otherwise the cut lines may turn out to be uneven, resulting in a leaky body), you need to decide on the location of the speakers. I made the center of the woofer at a height of 400 mm. from the floor. The HF and midrange speakers were embedded almost at the very top of the front panel (taking into account the “convenience” of subsequent assembly). The angle between their centers is approximately 30 degrees from the horizontal (the midrange link is below the HF link). I placed the bass reflex under the woofer (its center lies on the vertical axis of the woofer), but it can be done anywhere - there is no difference. The only thing I would advise is to do one FI, and not several. The diffuser holders of the bass and midrange sections can be “recessed” into the body for beauty, but I did not do this. The sharp corner of the hole for the woofer needs to be slightly rounded. After all that has been done, we assemble the body, taking into account the above nuances. We leave one of the side walls unscrewed. After the boxes (without the side walls) are ready, we move on to finalizing the speakers. The weakest link in the S-90 is the 20GDS midrange driver. He makes unpleasant noises. It seems like the sound is coming from a cardboard box. I tried to change it to 20GDSh broadbands, but I didn’t notice much result. There is also a theoretical possibility of installing a 35-watt midrange (35GDS) instead of a 20GDS, but for a pair of such heads you will have to fork out another 700 rubles. In addition, if you change the speakers, you will need to calculate a new filter, and this will not be a modernization, but the manufacture of a new one acoustics. So I tried to get a good sound from the 20GDS. So, let's go. We take a Soviet casein ball for table tennis (Chinese ones will not work - they have a different material). Carefully saw it into two parts along the seam. Sand all the unevenness of the ball halves with fine sandpaper. It is necessary to ensure that the halves fit freely and without gaps onto the dust caps of the midrange speaker (the bulge in the middle, who doesn’t know). After this, we install the halves of the balls on a film case (for convenience further actions ). Then degrease the convex surface of the halves using cotton wool and alcohol. It is better not to pay attention to the temptation to “degrease” with alcohol from the inside, otherwise delicate work with the speakers will lead to the purchase of new ones. After degreasing, the surface should not be touched with hands. Now we dilute the epoxy resin with the hardener in a ratio of 1:2 (two parts of the hardener). Next, apply a very thin layer of the resulting mixture onto the fat-free surface of the hemispheres. Remove excess mixture with a piece of newspaper and leave to dry for 15 minutes. Then we obtain graphite powder from the lead of a simple pencil. To do this, you need to “rub” the pencil with fine sandpaper. After this, generously sprinkle the dried surface of the halves with powder and gently rub it with a cotton swab, constantly adding powder. When the hemispheres acquire a strong metallic shine, everything is ready. All that remains is to glue them on top of the dust caps of the speakers. “Super Cement”, which is sold in every household, is quite suitable for this purpose. store. When gluing, it is necessary to observe two parameters: 1) the halves must be located strictly in the center of the speakers, 2) the adhesive seam must be sealed, otherwise there will be no result in the work done. Personally, before doing anything with my speakers, I practiced on an old torn diffuser, which I advise you to do. After all this has been done, the speakers should dry thoroughly. We will take into account the remaining points of improvement when we insert the speakers into the housing. I also heard that a positive result is obtained if you glue the diffuser cap onto the speaker rod with the convex side inward. I haven’t tried this method, but they say that the result of such a modification is zero. Next we get to the HF link (6GDV-16). I would advise you to clean the dirt from the gap in the magnet (all tweeters have it there), place a piece of fluffy cotton wool under the dome (to absorb HF waves going under the dome) and coat the outside of the rim of the dome base with a guerlain solution (we dissolve guerlain in gasoline until a viscous substance forms). mass, but so that it drips from the brush). If you don't do this, it's okay. Anyway, after these steps, only an experienced person with a “trained ear” can discern improvements in the sound. Now let’s modify the filter (so that no whistling can be heard from the tweeter). To do this, we solder the capacitor and the coil in series and solder it all in parallel to the filter, to the output of the high-frequency speaker. Inductance and capacitance can be taken in any way, the main thing is that their product is equal to 2.82 (μF * mH). I will tell you what wires to use next. We will take the rest into account during final assembly of the case. Personally, I managed to “pin” another tweeter-10GDV-16 from a friend (by the way, thanks to him for his help). Its dome is made of fiberglass. To install it, I had to re-solder the filter a little, but the sound turned out better. A pair of these tweeters in the store costs 640 rubles. So if you want, you can buy it - it’s up to you. I didn't touch the subwoofer at all. I just washed off all the dirt from the suspension with the same alcohol. So, when the speakers are completely ready for installation, we move on to the next steps. First we will make a round bass reflex (diameter 70 and length 180 mm). It can be rolled up from thick cardboard, but I managed to find a plastic pipe for 70 in my garage - it fits perfectly into the interior of the speaker. You can also make the FI rectangular in cross section, but the presence of corners negatively affects low frequencies. If anyone needs it, here are the dimensions of the rectangle: 38.5 * 100 and 175 mm long. With this option, the “bottoms” will be rougher. Next, let's move on to the filter. We buy an acoustic cable (about 25-30 rubles per meter, no steeper is needed) with a cross-section of 2.5 mm. We change ALL the wires on the filter and the wires going to the speakers. We also use this wire to connect the LC circuit we assembled earlier. All filter controls (decibel control, low-pass and high-pass resistors - on different versions S90 they are in different places; I had the regulators at the back) remove them from the diagram. We change the wires coming from the amplifier to well-shielded ones (in a thick rubber winding), with a cross-section of 3 mm. You can use simple ones, but then there will be more signal loss in the wire. Finally, we remove the copper filter connectors into which the wires from the amplifier were connected - it is better to solder them directly. Now we are starting to slowly put it all together. Let's start by installing the speakers. The HF head must be isolated from the overall volume of the housing. This can be done in any way. I placed the tweeters on podiums made of plywood, and sealed the hole in the housing with a fiberboard cover. M/s body and fiberboard inserted a rubber gasket. You can also not make the holes for the tweeters through. The midrange speaker must be inserted into the amplifier (panel acoustic impedance ), which should be filled with cotton wool. Before installing the PAS into the body, you must wrap it with a bandage. You can put a thin layer of cotton wool under the bandage. I took the PAS from Vega 50AC - 106 - it steals less volume inside the column. I installed it from inside the case, i.e. I screwed it to the inside of the front wall of the housing close to the hole for the midrange head. I put a rubber gasket between the front wall and the PAS and sealed the joint with sealant, and generously wrapped the PAS itself with cotton wool and a bandage. After the PAS is installed, we insert the speaker, having previously wrapped it with padding polyester (we wrap it around a metal diffuser holder). Again, place a rubber gasket under the speaker. Gaskets are obtained well from a car inner tube. It is advisable to glue all connections. Next we install the woofers. To do this, you need to make bags for them from an ordinary rag potato bag. I cut two rubber pads that fit the woofer, then glued them together with the edges of a two-ply rag bag between them. The result was something similar to a vacuum cleaner bag. I did the same for the second speaker. After this, we screw the woofers into place, immersing them in bags. Again, all connections need to be properly glued. Then we insert the FI, also wrapping it with cotton wool and a bandage. When the speakers are in place, insert the filter. We install the LC circuit we assembled on plywood measuring 70*70 and screw it all on at the level of the tweeter. We place the filter itself on the back wall of the housing (put a piece of batting between the housing and the filter). Next we make a “sound-absorbing” bottom. To do this, we take a bag (made of white material, not fabric - I don’t know what the material is called) and make a two-layer bag out of it. We fill it with sifted sand (5-6 kg) and sew it up. Then glue it to the bottom of the column. After this, we cover the ENTIRE inner surface of the speaker with sound-absorbing material (batting, padding polyester, felt). The thickness of the upholstery layer should be approximately 10 mm. - no more. You can sew upholstery from several layers of material. I found suitable batting in my grandfather's garage and glued it on PVA. For those who don’t have a grandfather with a garage, you can tear up an old sweatshirt or mattress. After all, the batting is sold in stores. We put all the wires (we first twist them together and wrap them with a bandage) under the upholstery. Solder the wires! (rather than connecting through plugs) to the speakers, observing the polarity. We also glue the remaining side wall and screw it into place, not forgetting about the sealant. All that remains is to place the speakers on conical legs (top down) with a height of 20-25 mm. You can order them from any turner for a bottle of vodka. To prevent the cones from pushing through the floor, you need to place them on coins. Now all that remains is to give the acoustics an aesthetic appearance. You can do it at your own discretion, at least gild it. I did it like this. I filled up all the uneven surfaces and “hidden” screw heads, then sanded the entire surface with a sander, then coated the speakers with a primer and finally painted them with matte black paint. I hid the “scary faces” of the speakers behind a black velvety fabric, stretching it over a frame made of a 10-bar. The sound became unrecognizable. The resulting acoustics are superior in quality to many foreign screens.

They are distinguished by an expanded range of reproduced frequencies, the introduction of an indication of electrical overload of loudspeakers and a new appearance. The recommended power of a high-quality household amplifier is 20-90 W. The preferred installation option is floor-mounted.

A distinctive feature of the acoustic system is the use of a loudspeaker with magnetic fluid “MANGO” as a mid-frequency link, which made it possible to increase the rated power of the loudspeaker and the speaker as a whole.

Specifications:Сг3.843.050 TU.

Shape of the frequency response of sound pressure measured along the acoustic axis: a) , b) ,

Specifications:

| Specifications | Meaning |

| Reproducible frequency range under free field conditions, Hz: | |

| 25...25000 | |

| , | 25...25000 |

| Uneven frequency response of sound pressure, dB, at the lower limit frequency of the reproduced frequency range relative to the average sound pressure level: | |

| -15 | |

| , | -14 |

| Uneven frequency response of sound pressure, dB, in the frequency range 100...8000 Hz relative to the average sound pressure level: | |

| ±4 | |

| , | ±4 |

| Level of characteristic sensitivity (characteristic sensitivity), dB, not less: | |

| 85 (0,338) | |

| , | 89 (0,56) |

| Directional characteristics of the speaker, dB, determined by the deviation of the frequency response of sound pressure, measured at angles of 25 ± 5° in the horizontal plane and vertical plane, from the frequency response measured along the acoustic axis of the speaker (0°): | |

| : | |

| in the vertical plane | ±8 |

| in the horizontal plane | ±6 |

| , : | |

| in the vertical plane | + 2 |

| -4 | |

| in the horizontal plane | +4 |

| -3 | |

| Harmonic distortion AC, %, determined by the total characteristic harmonic coefficient at an average sound pressure level of 90 dB at frequencies, Hz, no more than: | |

| 250…1000 | 2 |

| 1000...2000 | 1,5 |

| 2000...6300 | 1 |

| Nominal electrical resistance (nominal value of total electrical resistance), Ohm: | |

| 4/8 | |

| , | 8 |

| 8 | |

| Minimum value of total electrical resistance, Ohm: | |

| 3,2/7,6 | |

| , | 7,6 |

| 7,0 | |

| Maximum noise (nameplate) power, W: | |

| , | 90 |

| 100 | |

| Maximum short-term power, W: | |

| , | 600 |

| Type of low-frequency acoustic design | bass reflex |

| Weight, kg | 23 |

| Dimensions, mm | 360x710x285 |

Design Features:

The enclosures of all modifications of the speakers are made in the form of a rectangular non-dismountable box made of chipboard veneered with valuable wood veneer. The thickness of the case walls is 16 mm, the front panel is plywood 22 mm thick. At the joints of the housing walls, elements are installed on the inside that increase the strength and rigidity of the housing.

IN speaker systems Head sets used:

- : ; ; ;

- ; : ; ; ;

- : ; ; .

The heads that make up the speakers are each framed with decorative blackened overlays, made by stamping from aluminum sheet, with four mounting holes. The midrange head is isolated on the inside from the total volume of the housing by a special plastic casing in the shape of a truncated cone. The LF head is located on the front panel along a vertical axis, and the MF and HF heads are shifted relative to this axis to the left or right. On the front panel there are also knobs for the midrange and treble level controls, and in the lower part there is a plastic overlay panel with a nameplate and a rectangular hole (100x80 mm), which is the bass reflex output. The nameplate shows frequency response curves corresponding to various positions of the level controls, as well as the name of the speaker and the manufacturer's logo. In addition, the front panel has special plastic bushings for attaching a decorative frame with fabric.

Crossover frequencies provided by filters: between low- and mid-frequency heads - 750±50 Hz, between mid- and high-frequency heads - 5000±500 Hz.

The design of the filters and the overload indication unit uses resistors such as BC, MLT, SPZ-38B, S5-35V, PPB, capacitors such as MBGO-2, K50-12, K75-I and inductors on plastic cast frames.

The removable decorative frame included in the kit is covered with knitted fabric with high acoustic transparency.

The delivery set includes four plastic feet, which can be attached to the base of the case if necessary.

Manufacturer: Riga Radio Plant named after. A. S. Popova.

Purpose: speaker systems are designed for high-quality sound reproduction as part of household electronic equipment.

Specifications:

3-way floorstanding speaker with bass reflex

Frequency range: 25 – 25000 Hz

Frequency response unevenness in the range 100-8000 Hz: ±4 dB

Sensitivity in the range 100-8000 Hz: 89 dB

Resistance: 8 ohms

Minimum impedance value: 7.6 ohms

Rated power: 35W

Maximum (nameplate) power: 90 W

Short-term power: 600 W

Installed speakers:

Dimensions (HxWxD): 710x360x285 mm

Description:

The acoustic system is similar except for the midrange speaker; the S-100F is installed with MAXID magnetic fluid. The speakers have two smooth playback level controls for midrange and treble. Adjustment limits are from 0 to -6 dB in the ranges of 500-5000 Hz and 5000-20000 Hz. In the “-6 dB” position the signal is weakened by 2 times. The speakers have LED indication of speaker overloads.

The body is made in the form of a rectangular non-separable box made of chipboard, veneered with valuable wood veneer. The wall thickness is 16 mm, the front panel is plywood 22 mm thick. At the joints of the housing walls, elements are installed on the inside that increase the strength and rigidity of the housing.

The heads are each framed with decorative black plates with four mounting holes. The midrange head is isolated on the inside from the total volume of the housing by a special plastic casing in the shape of a truncated cone. The LF head is located on the front panel along a vertical axis, and the MF and HF heads are shifted relative to this axis to the left. IN top corner The front panel contains overload indicators, and in the lower part there is a rectangular bass reflex hole, measuring 108x35 mm and tuning frequency 25 Hz. The nameplate on the midrange and treble regulators shows the frequency response curve and the manufacturer's logo. In addition, the front panel has bushings for attaching a decorative frame with fabric. On the rear wall, in the lower part, a block with terminals and a nameplate are attached. The set includes grills with acoustically transparent fabric.

The internal volume of the speaker is 45 liters. To reduce the influence on the frequency response of sound pressure and the sound quality of the speaker resonances of the internal volume of the housing, it is filled with a sound absorber, which is mats of technical wool, covered with gauze.

Inside the case, on one board, there are electrical filters that ensure separation of the speaker bands. The frequency section between LF/MF is 750±50 Hz, between MF/HF - 5000±500 Hz. The design of the filters and the overload indication unit uses resistors such as BC, MLT, SP3-38B, S5-35I, PPB, capacitors such as MBGO-2, K50-12, K75-11 and inductors on plastic cast frames.

Modification of 35AC-212 (S-90) with original speakers and switches.

According to the prospectus of the 90s, the Riga Radio Plant mass-produced two models of acoustic systems: 35AC-212 or “S-90” and 35AC-012 in the modifications “S-90B”, “S-90D”, “S-100B”. The time has come to modify the older model 35AC-212, as well as its predecessor 35AC-1, which have a similar set of speakers.

These models have switches for the level of attenuation of the energy supplied to the midrange and tweeters, allowing you to adjust them to the level of the woofer and adjust the system to specific listening conditions. All this is good, of course, but it “thumps and clicks” no matter how you turn the switches. I want it to be musical. Somehow I was talking about alternative thoughts about finalizing the S-90. These thoughts happily dissipated without being realized. They were replaced by others, more interesting ones. It seemed the most promising to use the “Nivaga 9” filter from the previous article and convert it to another set of speakers, and leave the midrange and high-frequency switches in their original factory form. The resulting filter diagram for the S-90 is shown in the figure. I propose to call it “Nivaga 10”.

A distinctive feature of the filter is the presence of resistors R1, R2, R3, R4, which provide direct potential contact of all speakers with the PA output and do not allow the phase response to deviate far from a linear frequency dependence. If you look closely at the diagram, you will notice that the resistance of these resistors is close to the active resistance of the corresponding speakers. Meticulous comrades can of course add the inductive equivalent of these speakers. I was lazy, because even in this form the sound quality completely satisfied me, but I didn’t have the opportunity to experiment in a sound chamber. Well, if you look even more closely at the circuit of the bandpass filter leading to the midrange speaker, you can see that it was created from a previously developed filter like “Nivaga 6 or 8” by replacing the speakers with equivalent resistors. Similarly in the lowpass and highpass filters resistors R1 and R3 are equivalent to the corresponding speakers. Therefore, this circuit with parallel connection of speakers is a logical development of the previous one with series connection of speakers, which means it retains all its advantages, which were written about in earlier articles. And at the same time, it creates new opportunities to move the cutoff frequency of all four filters included in the circuit independently of each other, controlling the peaks and dips in the frequency response of the speaker, which was not the case in the previous circuit.In the specific case of this circuit, I sought to expand the cutoff frequencies of the low and midrange speakers, as well as the cutoff frequencies of the midrange and high frequencies speakers by half an octave. The results are brilliant. Elastic bass, stereo panorama, volume, clear mids - everything that the ear of a music lover craves is present in the modified S-90 speakers.

The fear that the introduced resistors would heat up was not justified. Their power is theoretically based. In practice, it can be reduced by 2 - 3 times, but the resistors must be wirewound.

Practice shows that not everything that I like suits others. Well, the proposed scheme is open to reasonable modifications, and I am ready for serious discussions.

This treatise was compiled on February 20, 2012.

| 35AC-012 | 35AS-1 (35AS-201) | 35AS-212 |

|

|

|

| S-90B | S-90B | S-90D, S-100D |

|

|

|

| S-90E | S-90F | |

|

|

Production of the three-way acoustic system "35AC-012" (S-90) began in 1975, "35AC-212" (S-90) since 1980. Bryansk Electromechanical Plant and Riga Radio Plant named after Popov. Price 1984 S-90 (35AC-212) – 150 rub.

The range of sound frequencies effectively reproduced by the acoustic system consists of the frequency response of three loudspeakers: low-frequency type - 30GD-2 (75GDN-1-4/8 or 75GDN-3), mid-frequency type - 15GD-11A (20GDS-1-8 or 20GDS- 3) and high-frequency 6GD-6-25 (6GDV-6-16 or 10GD-35 or 10GDV-3) which, with their frequency response, complement and equalize the overall amplitude-frequency characteristic of the acoustic system, which is equal to - 25...25,000 Hz. Speaker input impedance 3.2 ohms. Speakers with an input resistance of 7.6 ohms were also produced. The speaker casing is non-separable, with the exception of its front panel; the speaker casing is made of 16 mm thick chipboard. The front panel of the speaker system is made of plywood, 22 mm thick. A special frame with dark fabric can also be placed on the front panel to give the speaker system a domestic rather than technical appearance. The speakers were produced in a mirror version. The speaker has a bass reflex tuned to a frequency of 31 Hz. The bass reflex output is located in the lower corner of the housing. The speaker has switchable frequency response controls for midrange and treble, which are located opposite the corresponding heads. Speaker dimensions 360x710x285 mm. Weight 30 kg.

Purpose and scope: for high-quality reproduction of music and speech programs in stationary living conditions (performance category UHL 4.2 according to GOST 15150-69). The S-90 acoustic system, developed in 1975, is the first domestic system that meets the requirements of international documents for Hi-Fi equipment.

The acoustic system 35AS-1 (35AS-201), developed at the beginning of 1977 by the Orbita design bureau of the Riga Radio Engineering Production Association, became the second speaker in the whole S-90 series.

It was used to complete the Viktorija 003 radio and the Allegro 002 electrophone, and was first shown at the Svyaz-75 exhibition. At that time, it was the best not only among domestic speakers, but also sounded better than many speakers from foreign companies. The speaker system has two step playback level controls for mid and high frequencies in the ranges of 500...5000 Hz and 5...20 kHz, respectively. Both regulators have three fixed positions: “Max”, “Norm” and “Min”. In the "Max" position, the signal is supplied to the HF head directly, and to the midrange - through a resistor equalizing the sound pressure. In the “Norm” and “Min” positions, the signal is attenuated relative to the “Max” position by 3 dB (1.41 times) and 6 dB (2 times), respectively. By switching the knob you change the timbre of the sound. To manipulate the switches, the decorative front panel must be removed.

Price 1978 35AS-1 – 110 rub.

Later modifications of this acoustic system “S-90B” and “S-90D” are distinguished by an expanded range of reproduced frequencies, the introduction of an indication of electrical overload of the loudspeakers and a new appearance. The recommended power of a high-quality household amplifier is 20-90 W. The preferred installation option is floor-mounted.

Price 1989 S-90B – 150 rub.

Price 1990 S-90D – 160 rub.

A distinctive feature of the “S-100B” acoustic system is the use of a loudspeaker with magnetic fluid “MANID” as a mid-frequency link, which made it possible to increase the rated power of the loudspeaker and the speakers as a whole. Specifications: Cr3.843.050 TU.

The Bryansk Electromechanical Plant produced a version of the 35AC-012 speakers called S-90E, externally similar to the SOYUZ 50AC-012, but with a different filter circuit, produced by the same company with a 75GD-3-4 low-frequency speaker on a PPU suspension.

S-90 clones with a similar set of heads were also produced, such as 50AC-012 Soyuz, 35AC-202 Romantika, 35AC-211 Amphiton.

Sound System ModificationsS-90:

|

Model |

Start of release |

Plant manufacturer |

|

35AS-1 (35AS-201) |

Riga PA "Radio Engineering" KB "Orbita" |

|

|

Bryansk Electromechanical Plant and Riga Radio Plant named after Popov |

||

|

Riga PA "Radio Engineering" |

||

|

Riga PA "Radio Engineering" |

||

|

Bryansk Electromechanical Plant |

||

|

Riga PA "Radio Engineering" |

Specifications

|

Characteristics |

35AC-012, |

35AC-1 |

S-90B, |

S-100B, |

S-90E 35AC-012 |

|---|---|---|---|---|---|

Reproducible frequency range under free field conditions, Hz |

|||||

|

Uneven frequency response of sound pressure, dB, at the lower limit frequency of the reproduced frequency range relative to the average sound pressure level |

|||||

|

Uneven frequency response of sound pressure, dB, in the frequency range 100... 8000 Hz relative to the average sound pressure level |

|||||

|

Level of characteristic sensitivity (characteristic sensitivity), dB (Pa/√W), not less |

|||||

|

Directional characteristics of the speaker, dB, determined by the deviation of the frequency response of sound pressure, measured at angles of 25 ±5° in the horizontal plane and 7 +3° -2° in the vertical plane, from the frequency response measured along the acoustic axis of the speaker (0°): in the vertical plane in the horizontal plane |

|||||

|

Harmonic distortion of speakers, %, determined by the total characteristic harmonic coefficient at an average sound pressure level of 90 dB at frequencies, Hz, no more than: 250...1000 |

|||||

|

Nominal electrical resistance (nominal value of total electrical resistance), Ohm |

|||||

|

Minimum value of total electrical resistance, Ohm |

|||||

|

Rated power, W |

|||||

|

Maximum noise (nameplate) power, W |

|||||

|

Maximum short-term power, W |

|||||

|

Weight, kg |

|||||

|

Dimensions, mm |

|||||

|

Internal volume of the speaker housing, dm 3 |

|||||

|

Set of heads |

|||||

|

Type of low-frequency acoustic design |

Bass reflex |

||||

Bass reflex cross-section dimensions, mm |

|||||

Bass reflex tuning frequency, Hz |

|||||

|

Crossover frequencies provided by filters. Hz: between low and mid frequency heads between mid and high frequency heads |

|||||

Frequency response graphs

Shape of the frequency response of sound pressure measured along the acoustic axis S-90 (35AC-012, 35AC-212)

Shape of the frequency response of sound pressure measured along the acoustic axis S-90B, S-90D, S-100B

Design Features

The enclosures of all modifications of the speakers are made in the form of a rectangular non-dismountable box made of chipboard veneered with valuable wood veneer. The thickness of the case walls is 16 mm, the front panel is plywood 22 mm thick. At the junctions of the housing walls and on the inside, elements are installed that increase the strength and rigidity of the housing.

The following sets of heads are used in acoustic systems:

S-90: 75GDN-1-4/8; 20GDS-1-8; 6GDV-6-16;

S-90B, S-90D: 75GDN-1-8; 20GDS-1-16; 6GDV-6-25;

S-100B, S-100D: 75GDN-1-8; Z0GDS-3; 6GDV-6-25.

The heads included in the AC “S-90” are each framed with decorative blackened overlays, made by stamping from aluminum sheet, with four mounting holes. The midrange head is isolated on the inside from the total volume of the housing by a special plastic casing in the shape of a truncated cone. The LF head is located on the front panel along a vertical axis, and the MF and HF heads are shifted relative to this axis to the left or right. On the front panel there are also knobs for midrange and treble level controls, and in its lower part there is a plastic overlay panel with a nameplate and a rectangular hole (100X80 mm), which is the bass reflex output. The nameplate shows frequency response curves corresponding to various positions of the level controls, as well as the name of the speaker and the manufacturer's logo. In addition, the front panel has special plastic bushings for attaching a decorative frame with fabric.

On the back wall of the S-90, in the lower part, there is a block with special terminals used to connect the supply wires. Each head on the front panel side is protected by a blackened metal mesh to prevent damage during transportation and operation.

The heads included in the “S-90B” and “S-100B” are framed by two decorative overlays made of plastic and then painted “metal” or black. One trim frames the midrange and tweeter heads, as well as the upper half of the front panel, the other – the woofer head and the lower half of the speaker front panel. The midrange, tweeter and bass heads are protected by metal meshes. Each of the overlays is secured with six decorative screws. The midrange head is isolated on the inside from the total volume of the housing by a special plastic casing in the shape of a truncated cone. The heads are located on the front panel along the vertical axis of symmetry of the speaker. The nameplate at the top of the front panel shows the sound pressure frequency response curve and gives the name of the speaker. In the upper right corner of the front panel there are speaker overload indicators by channel, and in the lower part there is a rectangular output hole (35X108 mm) of the bass reflex, the tuning frequency of which is 25 Hz. On the rear wall of the speaker there is a nameplate with the main technical characteristics and a block with clamps for connecting the connecting cord, as well as sound pressure level controls at medium and high frequencies.

The heads included in the “S-90D” are each framed with decorative overlays and protected by a mesh; The arrangement of the heads is similar to that in the “S-90”. On the front panel, in addition, there are: indicators of overload of the loudspeaker heads, regulators of the sound pressure level of the midrange and high-frequency loudspeaker heads, and a nameplate with the name of the speaker. At the bottom of the front panel there is a rectangular output hole (95x75 mm) of the bass reflex, the tuning frequency of which is 31 Hz. The front panel also has plastic bushings for attaching a decorative frame with fabric. On the rear wall of the speaker there is a nameplate with the main technical characteristics and a block with special clamps for connecting the connecting cord.

The internal volume of all modifications of the AC is 45 dm 3. To reduce the influence on the frequency response of sound pressure and the sound quality of speakers from the resonances of the internal volume of the housing, it is filled with a sound absorber, which is mats of technical wool, covered with gauze. The mats are located and fixed on the inner surfaces of the housing walls.

Electrical filters are mounted inside the housing on one board, providing electrical separation of low-, mid- and high-frequency speaker bands. Electric filters of all modifications of speakers have the same design and fundamental electrical circuits.

Crossover frequencies provided by filters: between low- and mid-frequency heads - 750±50 Hz, between mid- and high-frequency heads - 5000±500 Hz.

The design of the filters and the overload indication unit uses resistors such as BC, MLT, SPZ-38B, S5-35V, PPB, capacitors such as MBGO-2, K50-I2, K75-11 and inductors on plastic cast frames.

The removable decorative frame included in the “S-90”, “S-90D” kits is covered with knitted fabric with high acoustic transparency.

The delivery set includes four plastic feet, which can be attached to the base of the case if necessary.

Filter circuits

Schemes S-90 - 35AC-012

Scheme S-90 - 35AC-212

Scheme S-90 - 35AC-1 (35AC-201)

When both level switches S1 and S2 are in the position shown in the diagram (“max”), the signal is supplied to the mid-frequency head BA2 through the sound pressure equalizing resistor R3, and to the high-frequency head V3 directly. When the SI switch is moved to the middle (“normal”) or second extreme position “min.” various voltage dividers are included in the circuit of head B2, as a result of which the average sound pressure created by the loudspeaker in the frequency range of 500 Hz.. 5 kHz is reduced by 3 or 6 dB, respectively. When switch S2 is set to the middle or second extreme position, voltage dividers are included in the circuit VZ heads. which leads to the same decreases in average sound pressure at frequencies above 5 kHz.

The voltage dividers use resistors MON (R2, R5) and PEV (the rest).

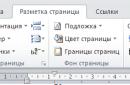

Schemes S-90B, S-90D, S-90F S-100B, S-100D, S-100F

Appearance of Filter S-90B